折りたたみワゴン

はじめに

折りたたみ式ワゴンはアウトドアシーンで最も汎用性の高い運搬ツールの一つであり、ケリーランドアウトドアーズでは製品ラインナップの新星です。12年以上にわたる製造とカスタマイズの経験を生かし、世界中のB2Bクライアントの実用的かつブランディングのニーズを満たすようデザインされた、幅広い折りたたみ式ワゴンを開発・供給しています。

コンパクトな収納と迅速な展開に理想的なシングルフォールディングとマルチフォールディング折りたたみワゴン、収納スペースを最大化するために設計されたダブルデッカーとエクステンデッドフォールディングワゴン、通気性の高いメッシュまたはオックスフォードファブリックのエクステンションを備えたレイズドフォールディングワゴンがラインナップされています。ヘビーデューティーな使用に最適なユーティリティー折りたたみワゴンは、キャノピーシェード、リクライニング構造、全地形対応機能など、より充実した機能を備えています。

耐久性と耐荷重性に優れたワゴンは、一般的に防水コーティングを施した600Dダブルレイヤー・オックスフォード生地を使用し、22mm以上のアルミニウム合金またはパウダーコーティングのスチールフレームで支えられています。オプションとして、ブレーキ付きオールテレイン・ホイール、伸縮式プルハンドル(62~105cm)、長い荷物を積載するためのフリップダウン・テールゲート、取り外し可能なテーブルトップなどがあります。耐荷重は50~200kg、容量は90Lから200L以上まで、モデルや構成によって異なります。

ケリーランドアウトドアーズでは、色、ロゴ、構造、アクセサリーのカスタマイズが可能なフルOEMサポートを提供しています。私たちのワンストップソーシングと低いMOQは、輸入業者やアウトドア製品ラインの拡大を目指すブランドオーナーにとって理想的な製造パートナーとなっています。私たちの折りたたみ式ワゴンがどのようにあなたのビジネスを向上させることができるか、ぜひご覧ください。

製品コレクション

折りたたみワゴンのプレミアムラインナップをご覧ください。

カスタム折りたたみワゴンを今すぐ入手 !

素材の選択

折りたたみワゴンの素材や機能的なアクセサリーについてご紹介します。

生地オプション

オックスフォード・ファブリック

600Dダブルレイヤー・オックスフォード生地は、折りたたみワゴンに最もよく使用される素材です。耐水性、引き裂き強度、耐久性を高めるため、PVC、PU、PEコーティングが施されています。ヘビーデューティーな使用に最適で、高い耐荷重をサポートし、屋外条件下でも構造的完全性を維持します。

ポリエステル・メッシュ生地

軽量で通気性に優れたポリエステル・メッシュ生地は、折りたたみ式ワゴンのサイド収納ポケットによく使われている。通気性を確保しながら、小物へのアクセスや安全性を保つことができる。耐荷重性はないものの、利便性と整理整頓を高める機能的な付加物として優れている。

折りたたみワゴンを作るために好みの素材を選ぶ

フレームオプション

金属丸管

アルミニウム合金製または粉体塗装された炭素鋼製の丸型金属管は、通常、多段折り畳み式ワゴンの四隅支持棒やメイン・ハンドル構造として使用される。耐荷重強度に優れ、軽量で、スムーズな折り畳みと展開機構をサポートします。

角形金属管

通常アルミニウムか炭素鋼で作られる角パイプは、一折りワゴンの前部と後部の構造フレームによく使われる。表面が平らなため安定性が高く、組み立ての位置合わせが容易です。これらのチューブは、コンパクトな折りたたみ形状を維持しながら大きな荷重を支えるのに理想的です。

楕円金属管

楕円形の金属管は、サイドフレームの補強やプル・ハンドルに使用され、洗練されたデザインと人間工学に基づいたグリップを提供する。様々な構造要素を接続するのに役立ち、強度と美観の両方で好まれています。さまざまな性能と重量の要件に合わせて、アルミニウム製とコーティング鋼製のオプションがあります。

ホイールオプション

PPおよびPVCホイール

最も費用対効果の高いホイール・オプションである。ハブは耐久性のあるポリプロピレン(PP)製で、タイヤ表面はPVC。一般的に幅の狭いホイールに使用されるこの組み合わせは、基本的な荷重支持を提供し、衝撃吸収や騒音低減を最小限に抑えた平坦な地形に適しています。

PPとPUホイール

ホイールハブは強靭なPP製で、外側のタイヤはPUフォーム製。PUはPVCに比べてクッション性と耐摩耗性に優れている。このタイプのホイールは、滑らかな転がり、優れた衝撃吸収性、静かな走行性能を提供し、屋内外の路面に最適です。

PPとEVAホイール

PPハブとEVAフォームタイヤを採用したこのホイールは、軽量で柔軟性に優れている。EVAはPUよりも柔らかく、衝撃を吸収するのに役立つが、耐摩耗性には劣る。転がりが静かで、芝生や砂地のような柔らかい路面に適しているため、このタイプのホイールがよく選ばれる。

PPおよびTPEホイール

PPハブとTPE(熱可塑性エラストマー)タイヤを採用。TPEは弾力性、グリップ力、耐久性に優れています。EVAやPVCに比べ、TPEはトラクションと衝撃吸収性に優れており、より険しい路面やオフロードの折りたたみワゴン用途に適しています。

アクセサリー・オプション

プラスチック部品

射出成形されたプラスチック部品は、主要なフレーム部分の接続とサポートに使用されています。これらの部品は耐久性に優れ、軽量で、さまざまな製品デザインに合わせて色をカスタマイズできるため、折りたたみワゴンの機能と見た目の魅力を高めています。

ポリプロピレン・ボード

PPボードは軽量で耐水性のある素材で、折りたたみ式ベースプレートの内層に使用されています。ファブリックベースの内側に縫い付けることで、ワゴンの構造を補強すると同時に、全体の重量を抑えて持ち運びや折りたたみを容易にします。

MDFボード

MDF(中密度繊維板)もベースボードの選択肢のひとつで、優れた剛性と平坦性を提供します。標準的なワゴンやヘビーデューティーなワゴンによく使用され、布製ベースに縫い付けられ、ギアを積み込む際に安定したバランスのとれたサポートを提供する。

発泡ポリエチレン

ワゴンの生地と生地の間のパディングとして使用されるEPEフォームは、柔らかさ、クッション性、衝撃吸収性を提供します。輸送中に壊れやすいものを保護し、ワゴンをベンチや簡易ベッドで使用する際の快適性を高めます。

フットブレーキ付き360°回転ホイール

ブレーキ内蔵の旋回車輪は、完全な方向制御と確実な位置決めを可能にします。不整地や傾斜面に最適なこのシステムは、ワゴンが静止しているとき、安全に所定の位置にロックできることを保証します。

サイドポケット

外側のサイドウォールに取り付けられた布製またはメッシュ製のポケットは、ツールや飲み物、小物などの収納に便利です。折りたたみ性に影響を与えることなく機能性を高めることができるため、アクセサリーを簡単に取り出したいユーザーに人気の追加装備となっている。

取り外し可能ホイール

コンパクトに収納できるよう設計された、取り外し可能な車輪は、折りたたみワゴンをより小さなフットプリントに折り畳むことを可能にします。使用後は簡単に車輪を取り外すことができ、トランクのスペースを節約したり、清掃やメンテナンスのために使用することができます。

キャンピングコット・スタイル

ワゴンの4辺を折りたたむと、キャンプ用コットとして使える平らな面になる特許デザイン。この両用構造が製品の汎用性を高め、ミニマリストのアウトドアユーザーにアピールしている。

折りたたみ式ベンチ

片側を折りたたみ、反対側を背もたれとして立てておけば、ワゴンが機能的なベンチに早変わり。キャンプ場や公園、フェスなど、屋外での休憩に最適な省スペースソリューションです。

自動引き込み式伸縮ハンドル

このハンドルは、90度までの自動復帰を可能にするスプリング機構を備えています。お好みの長さまで伸ばしたりロックすることができ、快適な引き心地と、収納効率を高める素早い収納を実現します。

減衰制御伸縮ハンドル

バネ式のハンドルとは異なり、このバージョンはダンピングシステムを採用しており、スムーズに角度を調整・固定することができます。自動引き込みを防ぎ、安定した位置決めと、変化に富んだ地形でワゴンを引いたり押したりする際の柔軟性を提供します。

取り外し可能なキャンピングカートカバー

ワゴンの外側のファブリックボディは金属フレームから取り外すことができ、クリーニングや交換が簡単です。このデザインは衛生面を向上させ、異なるブランドや季節のパターンに合わせたカスタマイズを可能にします。

ピックアップスタイルの折りたたみ式テールゲート

ピックアップトラックのテールゲートのように機能するリアフォールディングパネル。開くと、室内スペースへの容易なアクセスを維持しながら、収納容量を増やすことができる。

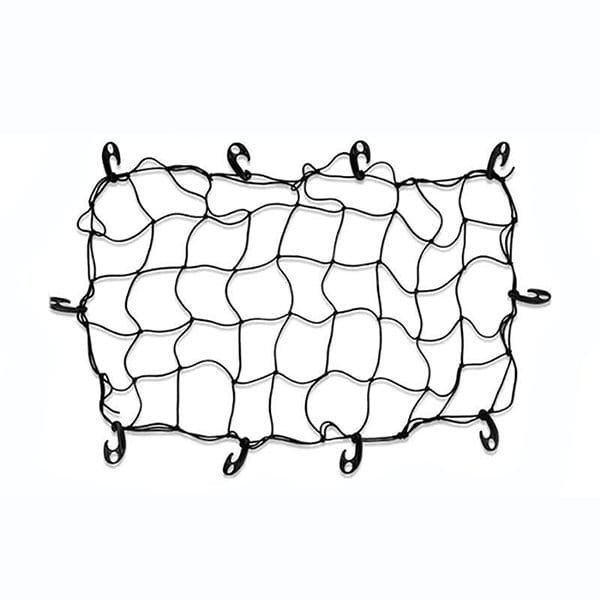

伸縮性開閉式ネット

伸縮自在で取り付けが簡単なこのネットは、運搬中のアウトドアギアを固定します。特にテントやチェア、クーラーなどのかさばる荷物に便利です。

取り外し可能な傘

ワゴンにクリップでしっかりと固定し、日陰と小雨を防ぐ追加型傘。取り外し可能なデザインなので、天候に応じて取り付けたり、収納したりできて便利。

取り外し可能なテーブルトップ

ワゴンの上にしっかりと取り付けられる取り外し可能なボードで、キャンプテーブルに早変わり。屋外での食事やワークスペースに最適で、平らで安定した表面を提供し、素早く設営・撤収できる。

取り外し可能な昇降式テーブルトップ

このテーブルトップには高さ調節可能な脚が付属し、スタンディングテーブルとしてもダイニングテーブルとしても使用可能。折りたたみワゴンの多くのモデルと互換性があり、アウトドアでの調理、交流、収納など多機能性を高めます。

取り外し可能なサンシェードトップ

ワゴンの上部に取り付け、直射日光から中身を守る布製のキャノピー。この日除け機能は、屋外マーケットやペットの輸送、子供向けのデザインに人気があります。

取り外し可能な収納バッグ

リアフレームに取り付けるよう設計されたこのバッグは、コンパートメントスペースを追加します。工具やケーブル、身の回り品の整理に最適で、必要に応じて取り外して別々に持ち運ぶこともできる。

取り外し可能なプッシュハンドル

この調節可能なハンドルは、引っ張る代わりに押すことができます。人間工学に基づいたコントロールと高さ調節のために回転させることができ、長距離や凸凹道での快適な操作性を向上させます。

取り外し可能な折りたたみ式ベースプレート

MDFまたはPP製の取り外し可能なベースプレートは、ワゴンの床に設置することで安定性を高めます。特に多段折りたたみ式ワゴンに便利で、取り外してコンパクトに収納できます。

キャリーバッグ

持ち手と伸縮性のあるバックルが付いたキャリーバッグは、折りたたんだワゴンをすっきりと収納できます。持ち運びには欠かせないバッグで、屋内や車内に保管する際、ホコリや傷からワゴンを守ります。

理想の折りたたみワゴンをカスタマイズ

製造工程

折りたたみワゴンの精密な製造工程をご覧ください。

ステップ1 - 製品設計

製品デザインは、折りたたみ式ワゴンの構造、寸法、耐荷重、機能性を定義します。フレーム、生地、車輪、付属品がスムーズに組み合わされるようにします。優れたデザインのワゴンは、ユーザーの使い勝手を向上させ、生産上の問題を軽減し、市場の需要や屋外での使用シナリオに基づいた柔軟なカスタマイズを可能にします。

ステップ2 - 素材の入荷

このステップでは、オックスフォード・ファブリック、メッシュ、金属チューブなど、すべての芯材を受け取ります。適切な取り扱いにより、材料が損傷や変形なく到着することを保証します。この段階での明確な分類とラベリングは、検査や生産ラインへの効率的な流れをサポートし、生産の遅れを最小限に抑え、材料の取り違えのリスクを低減します。

ステップ3 - 材料検査

素材は品質と一貫性をチェックされる。生地は光線透過率と厚さ試験を受け、金属管は直径、肉厚、塩水噴霧試験による耐食性を測定します。このようにして、適格な素材だけが生産に投入され、製品の耐久性と顧客満足が保証されるのです。

ステップ4 - プラスチック射出

ハンドル、ジョイント、ホイールハブなどのプラスチック部品は射出成形される。特定のデザインにはカスタム金型が使用され、色はクライアントのブランディングに合わせて調整することができます。この工程は、最終製品全体の精密なフィット感、強度、美観の一貫性を保つために非常に重要です。

ステップ5 - 生地の裁断

デジタルテンプレートに基づき、ファブリックパネルを正確に裁断します。適切な裁断を行うことで、後の縫製に必要な一貫した寸法が確保され、ズレや組み立ての問題を回避することができます。この段階での精度は、製品の外観、強度、金属フレームとの構造的統合に直接影響します。

ステップ6 - シルクスクリーン印刷

お客様のご要望があれば、ロゴやグラフィックデザインをシルクスクリーン技法でファブリックパネルにプリントします。このオプションのステップにより、ブランドの認知度が高まり、パーソナライズされたタッチが加わります。不要な場合は、そのまま縫製に進み、ワークフローを合理化します。

ステップ7 - 生地の縫製

パネルは最終的なワゴンカバーに縫い付けられ、ストレスポイントには補強ステッチが施される。サイドポケット、メッシュパネル、フォームレイヤーなどの部品は一体化されている。縫製後、各カバーは完全な検査を受け、構造上の完全性と仕上げの品質を確保した後、組み立てに移る。

ステップ8 - 金属管の切断

金属管は、CNC制御装置で正確に切断されます。長さと角度の精度は、安定した組み立て、折り曲げ性能、耐荷重のために不可欠です。高い切断精度により、材料の無駄が削減され、その後の曲げ加工や溶接工程が問題なく進むようになります。

ステップ9 - 金属管の曲げ加工

それぞれの金属管は、特注の治具を使って設計仕様に従って曲げられる。オペレーターが手作業で曲げ工程をコントロールし、角度やカーブが構造上のニーズを満たすようにします。曲げの精度は、折りたたみのスムーズさとフレーム全体のアライメントに影響します。

ステップ10 - 金属の応力緩和

金属管は切断・曲げ加工後、応力除去工程を経て内部張力を除去します。これにより、経時的な変形が防止され、特に高荷重や折り畳みと展開の繰り返しによる長期的な構造安定性が向上します。

ステップ11 - パンチング

パンチングにより、リベット、ファスナー、ジョイント接続用の穴を開ける。カスタム治具は、後の位置合わせのために穴を正確に位置決めするために使用されます。この工程での正確さが、スムーズな組み立てと、すべての接続点での一貫した機械的強度を保証します。

ステップ12 - 金属溶接

溶接は、ホイール・サポートやハンドル・マウントなど、恒久的な接続が必要な主要フレーム部品を接合する。量と設計に応じて、手動またはロボット溶接が使用されます。質の高い溶接は、積載能力とワゴン構造全体の安全性を向上させます。

ステップ13 - パウダースプレー

金属フレームには、お客様ご指定の色の粉体塗装が施されます。これにより、滑らかな仕上がり、錆びにくさ、美観が向上します。また、粉体塗装は耐候性を高め、長期間の屋外使用にも適しています。

ステップ14 - リベッティング

リベットは、接合部、ヒンジ、およびその他の溶接されていない接続部を固定するために使用されます。精密なリベット打ちは、必要な部品の回転や折りたたみを可能にしながらも、安全で耐久性のある組み立てを保証します。このステップは、使いやすさと製品の寿命に直接影響する。

ステップ15 - 組み立て

フレーム、車輪、生地、ハンドル、付属品など、すべての部品が組み立てられ、折りたたみワゴンが完成する。この工程では、入念な位置合わせと各段階での品質チェックが要求される。最終承認の前に機能テストが行われる。

ステップ16 - 製品テスト

完成したワゴンはそれぞれ、引っ張る力、耐荷重、車輪の回転、安定性などのテストを受ける。これらのテストに合格した製品だけが、梱包へと進む。これにより、安全性、性能、国際規格への適合が保証される。

ステップ17 - 梱包

折りたたみワゴンは、ブランドの箱、保護カバー、またはカスタムキットを使用して、クライアントの要件に応じて折りたたみ、梱包されます。梱包は、輸送中に製品を保護すると同時に、輸送コストを削減するために容積を最適化する必要があります。ラベリングやバーコードもここで行われる。

ステップ18 - 倉庫保管

最終製品は、在庫管理と出荷準備のために倉庫に移される。整理された保管により、効率的な積み込みと注文の履行が保証されます。倉庫管理には、最終的なQAサンプリングや、特別な梱包や出荷指示の処理も含まれます。

折りたたみワゴンの製造工程に関する詳細

カスタマイズ・ハイライト

折りたたみ式ワゴンをパーソナライズして、ブランドのアイデンティティを反映させる

生地染色

生地染色では、お客様がご希望のワゴン生地の色をお選びいただけます。オプションで耐水性のためのPU/PVC/PEコーティングを施し、パントンにマッチした色合いを幅広く提供しています。このようなカスタマイズは、製品をブランドの美学に沿わせ、特に小売店や販促用途では市場での差別化を向上させます。

シルクスクリーン印刷

シルクスクリーン印刷は、1色または複数色を使用したシンプルなロゴやグラフィックに最適です。ワゴン生地にシャープで耐久性のあるブランディングが可能です。この方法は、企業ロゴやキャンペーンスローガン、アイコニックなビジュアルに広く使用され、屋外環境での長期的な視認性とブランド認知をサポートします。

熱転写印刷

熱転写印刷は、高精細な多色グラフィックやグラデーションロゴを可能にします。複雑なデザインやフルカラーのブランディングに最適です。プリントは熱と圧力で生地に接着され、鮮やかで耐摩耗性のある仕上がりを実現し、競争の激しい小売市場でブランドの品質を高めます。

カスタムインジェクション

ハンドル、ジョイント、ホイールハブなどのプラスチック部品は通常、標準的な黒色です。しかし、カスタム射出成形では、お客様が指定された色でこれらの部品を製造することができ、一貫したブランド・アイデンティティを強化し、ワゴン全体の視覚的一貫性を高めることができます。

パウダーコーティング

金属フレームには、RALまたはPantoneのカスタムカラーで粉体塗装を施します。これは耐腐食性と耐久性を保証するだけでなく、ワゴンをブランドや季節のカラーテーマに合わせることで、小売店や販促用の商品アピールを高めます。

レザーラベル

レザーラベルは、ロゴやアートワークをレーザー彫刻またはエンボス加工し、ワゴン生地に縫い付けることができます。高級感とヴィンテージ感が加わり、ハイエンドやライフスタイル志向の製品ラインに最適です。レザーラベルは、ブランドのクラフトマンシップと独自性を強化します。

ゴムラベル

ラバーラベルは、マルチカラーのロゴやエンボス加工の3Dブランディングに最適です。耐久性、耐候性に優れ、ワゴンのさまざまな位置に縫い付けることができます。このオプションは、手触りの良いテクスチャーを追加し、険しい屋外環境でのブランドの視認性を高めるのに役立ちます。

織ラベル

織物ラベルは、洗練されたプロフェッショナルなブランディング要素を提供し、織物の糸パターンを通して詳細なロゴやテキストを表示します。これらは通常、布地の縫い目や目に見える部分に縫い付けられ、屋外での長期間の使用後でもブランドの識別が長続きします。

洗濯ラベル

洗濯ラベルには重要なお手入れ方法と素材構成が記載されています。これらのラベルは、ブランド名でカスタマイズし、ワゴン生地の内側に縫い付けることができます。これらのラベルは、国際的な小売のための規制遵守を保証し、エンドユーザーに不可欠な使用法とクリーニング情報を提供します。

キャリーバッグ

キャリーバッグにはカスタムロゴやグラフィックを印刷することができ、ワゴンの保管時や持ち運び時にもブランドの露出を確保することができます。このアクセサリーは製品価値を高め、パッケージやアクセサリーに一貫したブランディングを求めるB2Bクライアントにとって特に有用です。

ハングタグ

ハングタグは、販売時に商品に付けられます。ロゴ、商品情報、QRコード、ブランドストーリーなどでカスタマイズすることができます。ハングタグは、小売店のブランディング、マーケティングコミュニケーション、プロフェッショナルなプレゼンテーションの構築に効果的なツールです。

マニュアル

折りたたみワゴンに同梱される印刷ガイドで、組み立て手順、お手入れのガイドライン、ブランド情報などを提供します。折り畳み式のリーフレットや小冊子など、さまざまな形式があり、マニュアルは多言語コンテンツ、イラスト、ブランド固有のスタイルでカスタマイズすることができます。

マスターカートン

大量輸送用の外装箱で、輸送中の製品の安全性を確保します。ブランディング、製品詳細、取り扱い説明などのカスタム印刷が可能で、小売や流通のニーズをサポートします。

ブランディングのニーズをお聞かせください

カスタマーレビュー

折りたたみワゴンとサービスに関するお客様の声をご覧ください。

よくある質問

折りたたみ式ワゴンの調達やカスタマイズに関するよくある質問と回答をご覧いただけます。

Q1.輸入ビジネスをしたことがないのですが、購入できますか?

- 返信 個人、法人を問わず、私たちは完全な販売サポートを提供しています。稀なケースとして、政府が会社名義での輸入を義務付けている場合を除き、私たちはすべてのパートナーに対して、デザイン、開発から生産、検査、ドア・ツー・ドアの発送に至るまで、エンド・ツー・エンドのサービスを提供しています。

Q2.卸売業者からの大量注文にも対応してもらえますか?

- 返信 もちろんです。安定したサプライチェーン、20近い中核パートナー工場、200を超えるサプライヤーにより、小規模小売店、大規模卸売店、チェーンストアのニーズにお応えします。私たちのチームと工場は、海外のお客様にサービスを提供してきた豊富な経験を持っています。

Q3.どのような国際認証を取得していますか?

- 返信 ほとんどの製品はCEおよびASTM規格に適合しています。お客様の市場で特定の認証が必要な場合は、テストサンプルを提供し、必要な承認を取得するお手伝いをいたします。

Q4.商品購入までの一般的な流れを教えてください。

- 返信

- 当社の営業チームにご連絡いただければ、お客様のニーズに基づいてプロジェクトを評価いたします。また、ビデオ通話、バーチャル工場見学、現地視察、第三者機関による監査などを通じて、当社についてより詳しく知ることができます。

- ご承認後、お客様のご要望に基づき、製品の設計やオプションのご提案をさせていただきます。

- デザインをご確認いただいた後、詳細な製品仕様とともにお見積もりを提出いたします。

- 価格とリードタイムにご同意いただいた後、必要に応じてサンプル確認のための請求書(PI)をお送りします。サンプル料金をお支払いいただき、7~15日以内にサンプルを作成し、調整が必要な場合はご連絡いたします。

- サンプルの写真/ビデオを共有し、承認を得ます。確認が取れましたら、宅配便にて発送いたします。変更が必要な場合は、ご納得いただけるまで修正いたします。

- サンプルをテストした後、大量生産を承認します。バルクPIをお送りします(または、価格とリードタイムを更新した後、POをお送りください)。

- ご注文の詳細が確定したら、合意された条件に従ってデポジットをお支払いください。

- ご入金後、制作を開始します。進捗状況や写真、ビデオでお知らせします。この間にパッケージのデザインと制作を行います。

- 完成の7~10日前に点検のご連絡をいたします(現場または自主点検報告書をお渡しします)。問題が発生した場合は、ご納得いただけるまで解決いたします。

- 発送前に、残金をお支払いいただきます(または、長期的にお取引いただいているお客様には、合意された条件に従ってお支払いいただきます)。

- お支払い後、発送の手配をいたします。弊社で手配する場合、送料は残金と一緒にお支払いいただきます。

- 貨物を追跡し、お客様が商品を受け取るまで最新情報を提供します。必要に応じて輸入手続きもお手伝いいたします。

- 納品後は、お客様のビジネスが円滑に進むよう、品質問題に対するアフターサービスを提供します。

Q5.大量注文の前にサンプルを提供してもらえますか?

- 返信 はい、有償サンプルを提供しています。料金は一括注文確認時に返金されます(ケースによります)。低コストのサンプルについては、送料をご負担いただければ無料でご提供できます。

Q6.最低発注量(MOQ)はいくらですか?

- 返信 MOQは製品によって異なります。一部の特定商品は50~100個から、標準モデルは300~1,000個です。大量注文の場合は、柔軟に調整いたします。お客様のニーズに基づいた正確なお見積もりは、弊社チームまでお問い合わせください。

Q7.生産にはどのくらいの時間がかかりますか?

- 返信 注文のタイミング、製品の種類、数量、カスタマイズの複雑さによって異なりますが、当社の標準的な生産期間は30~45日です。

Q8.ロゴやデザインをカスタマイズしてもらえますか?

- 返信 そう、私たちのコアビジネスは、お客様が商品をカスタマイズし、さまざまな形でブランディングを加えるお手伝いをすることです。これにより、お客様独自のブランドプロモーションと販売をサポートします。

Q9.ブランドタグやロゴ印刷など、パッケージのカスタマイズは可能ですか?

- 返信 はい、私たちのプロのデザインチームは、パッケージのドラフトを作成し、オプションについてお客様と議論し、最終製品に最適なソリューションを最終決定することができます。

Q10.中国からの送料と所要日数を教えてください。

- 返信 費用は注文量と仕向地によって異なります。弊社は信頼できるロジスティクス・パートナーと協力し、海上、航空、道路、鉄道、または複合輸送オプションの最新見積もりを提供することができます。

Q11.ロジスティクスや輸送サービスを提供してもらえますか?

- 返信 はい、ワンストップサービスプロバイダーとして、費用をご負担いただければ、ドア・ツー・ドアの物流をご提供いたします。複数の配送オプションからお選びいただけます。

Q12.輸入書類の作成はお願いできますか?

- 返信 輸出書類作成、通関手続きはお任せください。当社の経験により、様々な市場要件に確実に対応いたします。

Q13.支払いについて教えてください。

- 返信 新規のお客様、またはUS$3,000以上のご注文の場合、30%のデポジットと出荷前の70%をお願いしております。リピーターのお客様や大量注文の場合、条件は交渉可能です。

Q14.品質管理はどのように行っていますか?

- 返信 当社の工場はISO 9001:2015規格に準拠しており、各生産段階で検査を行っています。報告書はご要望に応じて入手可能です。

Q15.御社の製品にはどのようなメンテナンスや手入れが必要ですか?

- 返信 当社の繊維製品および金属製品は、特別な手入れは必要ありません。取扱説明書または弊社の営業チームの指導に従うだけです。ご不明な点がございましたら、お気軽にお問い合わせください。

Q16.保証や返品について教えてください。

- 返信 製造上の欠陥については最低1年間の保証を提供し、返品は個別に対応する。

ケーススタディ

折りたたみワゴンのお客様独自のニーズに合わせたソリューションをご紹介します。

ビジネスパートナーになる準備はできていますか?

ご連絡をお待ちしております。

12年のノウハウに裏打ちされたプレミアム・アウトドアギアで商品ラインを拡大しましょう。カスタムデザイン、信頼性の高い生産、グローバルなロジスティクスでお客様のビジネスの成長をサポートします。シームレスなサービスと革新的なソリューションのために私たちと提携してください。お客様のニーズを共有し、一緒に素晴らしいものを作りましょう!