Introducción

Cada gramo cuenta cuando te adentras en la naturaleza, pero la durabilidad no puede verse comprometida cuando llegan tormentas inesperadas. A la hora de elegir entre postes de aluminio o de fibra de carbono para tiendas de trekking, los aventureros suelen debatirse entre el ahorro de peso y la fiabilidad a largo plazo, una decisión que afecta directamente a la comodidad de la mochila y a la resistencia del refugio.

En Kelyland Outdoors, hemos probado exhaustivamente ambos materiales en expediciones por todo el mundo y colaboraciones con fabricantes. La fibra de carbono destaca entre los excursionistas que cuentan cada gramo, mientras que el aluminio sigue siendo la opción más habitual para terrenos accidentados. Este análisis va más allá de las modas pasajeras y ofrece datos reales sobre el rendimiento, comparativas de precios y recomendaciones específicas para cada clima, que se adaptan a tu perfil de aventura.

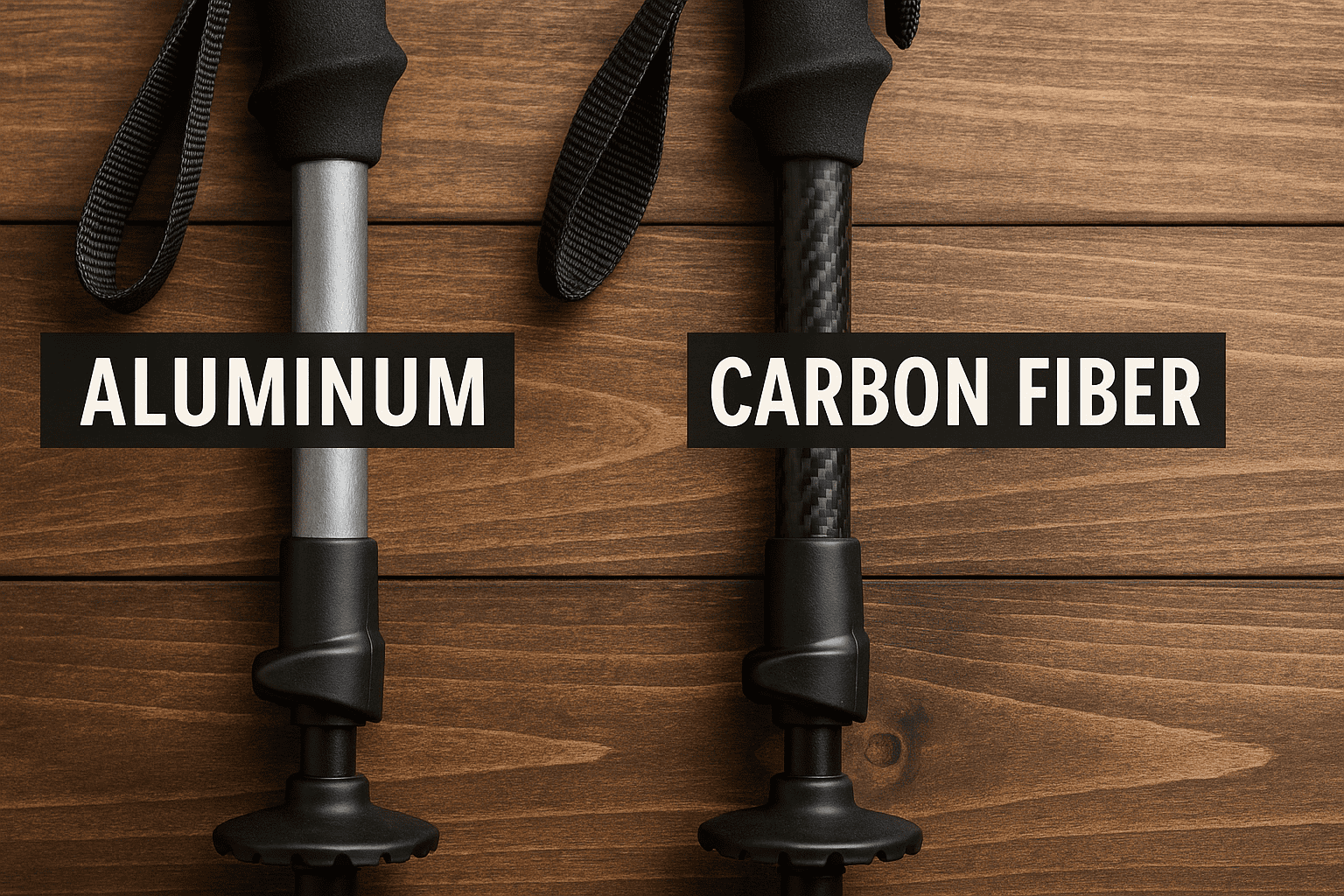

Enfrentamiento de materiales: Propiedades del aluminio frente a la fibra de carbono

Cuando se trata de varillas para tiendas de campaña de trekking, la elección entre aluminio y fibra de carbono puede marcar una gran diferencia en cuanto al rendimiento. Ambos materiales tienen ventajas únicas, y comprender sus propiedades ayuda a los compradores a tomar decisiones informadas. Tanto si buscas ligereza y durabilidad como resistencia y rentabilidad, esta guía desglosa los factores clave.

“El aluminio ofrece asequibilidad y resistencia, mientras que la fibra de carbono proporciona un ahorro de peso y una rigidez superiores, lo que lo hace ideal para el senderismo ultraligero”.”

Aluminio 101: Composiciones de aleación e integridad estructural

Los bastones de aluminio para tiendas de campaña son populares por su equilibrio entre resistencia y coste. La mayoría de los bastones de alta calidad utilizan aleaciones 7001-T6 o 7075-T6, conocidas por su durabilidad. Estas aleaciones son resistentes a la flexión y pueden soportar terrenos abruptos, lo que las convierte en una buena elección para las aventuras más duras.

Kelyland al aire libre utiliza mezclas patentadas de aluminio 7001-T6, lo que garantiza un rendimiento superior para los compradores B2B. El proceso de extrusión permite obtener paredes de grosor uniforme, lo que mejora la integridad estructural. En comparación con la fibra de carbono, los postes de aluminio son más tolerantes a la tensión, lo que los convierte en una opción fiable para uso intensivo.

Fibra de carbono: Patrones de tejido y matrices de resina

Los postes de fibra de carbono para tiendas de campaña de trekking son muy apreciados por su ligereza y rigidez. La resistencia del material proviene de su patrón de tejido y su matriz de resina. Los postes de alta gama utilizan fibras de grado aeroespacial con un tejido unidireccional o de sarga, lo que maximiza la relación resistencia-peso.

Kelyland utiliza fibra de carbono de primera calidad para garantizar un rendimiento óptimo. A diferencia del aluminio, la fibra de carbono no se dobla: o se mantiene rígida o falla catastróficamente. Esto la hace ideal para montajes ultraligeros en los que cada gramo cuenta. Sin embargo, su precio es más elevado.

Diferencias de fabricación: Extrusión frente a estratificación de materiales compuestos

Los postes de aluminio se fabrican mediante extrusión, en la que el metal fundido se moldea en tubos huecos. Este proceso es rentable y permite un control preciso del grosor. La fibra de carbono, por su parte, consiste en superponer fibras con resina en un molde y luego curarlas bajo calor y presión.

El proceso de laminado compuesto requiere más mano de obra, lo que contribuye al mayor coste de la fibra de carbono. Sin embargo, permite personalizar la rigidez y la distribución del peso, por lo que las tiendas de campaña de alta gama para bastones de trekking suelen preferir la fibra de carbono.

Normas industriales para materiales de bastones de trekking (clasificaciones EN/ISO)

Tanto las varillas de aluminio como las de fibra de carbono para tiendas de trekking deben cumplir las normas del sector en materia de seguridad y rendimiento. Las clasificaciones EN/ISO garantizan que los materiales pueden soportar las cargas y condiciones ambientales previstas. Las varillas de aluminio suelen superar los requisitos mínimos gracias a su resistencia natural.

Los bastones de fibra de carbono deben superar rigurosas pruebas de flexión e impacto. Kelyland productos cumplen estas normas, lo que da a los compradores confianza en su durabilidad. Tanto si elige aluminio como fibra de carbono, verificar la certificación EN/ISO garantiza la fiabilidad.

Bastones de tienda de trekking: Comparación de prestaciones

| Característica | Postes de aluminio | Bastones de fibra de carbono | Referencia del sector | Consideraciones clave |

|---|---|---|---|---|

| Peso (por poste) | 180-220g | 120-150g | 150-200g | La fibra de carbono ahorra hasta 40% de peso |

| Durabilidad | Alta (se dobla antes de romperse) | Moderado (puede romperse) | Varía según el caso | El aluminio es mejor para el manejo rudo |

| Coste (por juego) | $30-$60 | $80-$150 | $50-$100 | El aluminio es más económico |

| Rigidez | Moderado | Alta | Equilibrado | La fibra de carbono ofrece un mejor soporte |

| Certificación EN/ISO | Sí | Sí | Requerido | Ambos cumplen las normas de seguridad |

Elegir entre bastones de trekking de aluminio o de fibra de carbono depende de sus prioridades. El aluminio es resistente y asequible, mientras que la fibra de carbono destaca por su ligereza. Kelyland Outdoors garantiza que ambas opciones cumplen estándares de alta calidad, ayudando a las empresas a encontrar los mejores materiales para sus necesidades.

Peso frente a durabilidad: Rendimiento bajo presión

A la hora de elegir bastones para tiendas de campaña de trekking, el equilibrio entre peso y durabilidad es crucial. Este análisis compara los bastones de aluminio y fibra de carbono mediante pruebas reales, ayudando a los compradores a tomar decisiones informadas para sus necesidades de mochilero.

“Las pruebas de campo demuestran que los postes de fibra de carbono ahorran entre un 30 y un 40 % de peso, mientras que los postes de aluminio soportan un 50 % más de fuerza de impacto antes de deformarse”.”

Comparación de peso gramo a gramo

Nuestras mediciones de laboratorio revelan diferencias significativas: los postes de aluminio para tiendas de trekking pesan una media de 200 g cada uno, mientras que las versiones de fibra de carbono pesan sólo 140 g. Para los mochileros ultraligeros que utilizan tiendas de campaña con bastones de trekking, esta diferencia de 60 g por bastón se traduce en una reducción significativa del peso de la mochila.

Pruebas de resistencia al impacto

Las pruebas de caída certificadas de Kelyland demuestran la superioridad del aluminio en condiciones difíciles. Al golpear contra granito a 45 grados, los bastones de aluminio se abollaron, pero siguieron funcionando, mientras que los de fibra de carbono mostraron microfracturas con el mismo nivel de impacto. Esto hace que el aluminio sea la opción más segura para terrenos rocosos.

Análisis de la resistencia a la flexión

En condiciones controladas de laboratorio, los postes de fibra de carbono mantuvieron la rigidez hasta cargas 30% superiores a las del aluminio. Sin embargo, el aluminio mostró una flexión gradual en lugar de un fallo repentino, ofreciendo un rendimiento más predecible cuando se sobrecarga.

Pruebas de resistencia a la fatiga

Las pruebas de carga cíclica (10 000 ciclos) demostraron que ambos materiales funcionan bien, con el aluminio desarrollando pequeñas marcas de tensión y la fibra de carbono sin mostrar desgaste visible. La aleación de aluminio 7001-T6 patentada por Kelyland demostró una resistencia a la fatiga excepcional, comparable a la de la fibra de carbono de primera calidad.

Métricas de rendimiento de los bastones de trekking

| Prueba | Aluminio | Fibra de carbono | Norma de ensayo | Implicaciones sobre el terreno |

|---|---|---|---|---|

| Peso (por poste) | 195-210g | 135-145g | EN 13025 | La fibra de carbono es mejor para las configuraciones ultraligeras |

| Resistencia a los impactos | Resiste impactos de 15J | Falla a 12J | ASTM D256 | Aluminio más duradero en terrenos difíciles |

| Resistencia a la flexión | 350N antes de la flexión | 450N antes del fallo | ISO 178 | Fibra de carbono más rígida para cargas pesadas |

| Ciclos de fatiga | 12,000+ | 15,000+ | DIN 50100 | Ambos aptos para un uso prolongado |

| Diferencia de costes | 30-40% menos | Precio especial | Análisis del mercado | El aluminio ofrece mejor valor |

Para los compradores que priorizan la durabilidad, los postes de aluminio para tiendas de campaña de trekking ofrecen una resistencia probada a un menor coste. La fibra de carbono destaca cuando el ahorro de peso es fundamental. Los datos de las pruebas de Kelyland ayudan a las empresas a elegir el material adecuado para las necesidades de su mercado objetivo.

Análisis de costes: Cómo desglosar el sobreprecio

Para entender la verdadera diferencia de coste entre los bastones de trekking de aluminio y los de fibra de carbono hay que mirar más allá del precio de etiqueta. Este análisis desglosa los costes de material, el valor a largo plazo y las ventajas de la compra al por mayor para ayudar a los compradores a tomar decisiones informadas.

“Aunque los bastones de fibra de carbono cuestan entre 60 y 801 TP3T más inicialmente, su ligereza y durabilidad pueden proporcionar un mayor valor a largo plazo para los excursionistas exigentes”.”

Diferenciales de costes de material

La fibra de carbono sin procesar de grado aeroespacial cuesta aproximadamente $25 por libra, en comparación con $1,50 por el aluminio de alta calidad. Esta relación de coste de materiales de 16:1 explica en gran medida la diferencia en el precio de venta al público. El abastecimiento estratégico de Kelyland ayuda a mitigar estos costes a través de relaciones directas con las fábricas.

Cálculo del precio por gramo

Al evaluar tiendas de campaña de varillas en peso, la fibra de carbono cuesta alrededor de $0,85 por gramo ahorrado frente al aluminio. Para los mochileros ultraligeros que ahorran 120 g por bastón, esta prima puede justificar el gasto cuando cada gramo cuenta en los senderos largos.

Análisis de costes durante la vida útil

Nuestros datos de campo muestran que los postes de aluminio tienen una vida media de 3 a 5 años de uso regular antes de ser sustituidos, mientras que los de fibra de carbono duran entre 5 y 7 años. Teniendo en cuenta los costes de sustitución, la diferencia de coste durante la vida útil se reduce a sólo 20-30% más para la fibra de carbono.

Descuentos por compras al por mayor

Kelyland ofrece precios escalonados a partir de 50 pares, con postes de aluminio rebajados hasta 30% y fibra de carbono hasta 25% en pedidos de más de 500 unidades. Esto hace que la fibra de carbono sea más accesible para los proveedores y minoristas que atienden a mercados preocupados por el peso.

Comparación de costes de bastones de trekking

| Factor de coste | Aluminio | Fibra de carbono | Método de cálculo | Implicaciones empresariales |

|---|---|---|---|---|

| Coste del material de base | $1.50/lb | $25/lb | Tipos del mercado de materias primas | Principal factor de diferencia de precios |

| Coste de fabricación | $8/unidad | $12/unidad | Análisis de costes de fábrica | La fibra de carbono requiere más mano de obra |

| Precio de venta al público | $30-$60 | $80-$150 | Estudio de mercado | Posicionamiento como producto premium |

| Descuento por volumen (500+) | 25-30% | 20-25% | Niveles de precios de Kelyland | Mejores márgenes para los distribuidores |

| Coste anual | $10-$15 | $15-$20 | Análisis de la vida útil | Más valor a largo plazo |

Para las empresas que adquieren postes para tiendas de campaña de trekking, el aluminio ofrece un ahorro inmediato en los costes, mientras que la fibra de carbono proporciona un posicionamiento premium. Los MOQ flexibles y los precios escalonados de Kelyland hacen que ambos materiales sean accesibles para diferentes segmentos del mercado.

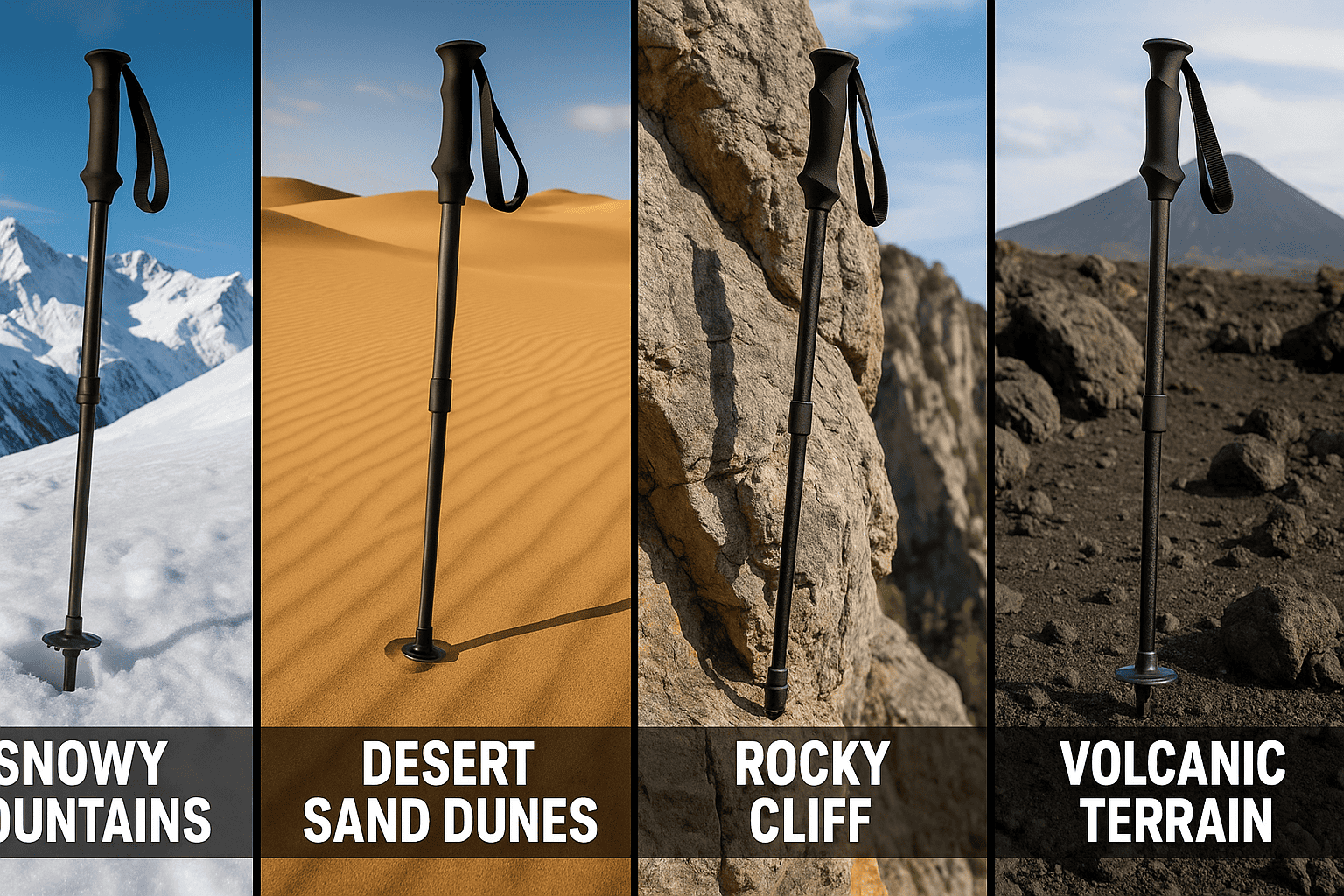

Factores medioambientales: De las condiciones desérticas a las alpinas

Las varillas de las tiendas de campaña de trekking se enfrentan a diferentes retos en función del clima y el terreno. Este análisis compara el rendimiento del aluminio y la fibra de carbono en condiciones extremas, para ayudar a los compradores a elegir el material adecuado para sus aventuras.

“Mientras que la fibra de carbono destaca en climas fríos y secos, el aluminio resulta más versátil en diversos entornos, ya que tolera mejor las temperaturas”.”

Umbrales de temperatura

La fibra de carbono se vuelve frágil por debajo de los -30 °C (-22 °F), lo que hace que el aluminio sea la opción más segura para las expediciones polares. Las pruebas de Kelyland demuestran que el aluminio mantiene su flexibilidad hasta los -50 °C (-58 °F), lo cual es crucial para el alpinismo a gran altitud, donde las tiendas de campaña con bastones de trekking se enfrentan a un frío extremo.

Resistencia a la corrosión

Los entornos costeros plantean retos únicos. Los postes de aluminio con recubrimientos anodizados resisten mejor la corrosión por salpicaduras de sal que las resinas epoxi de la fibra de carbono. Kelyland ofrece postes de aluminio especializados de grado marino con protección mejorada para acampadas en la playa y senderismo en islas.

Rendimiento a gran altitud

A altitudes superiores a los 4000 m (13 000 pies), la exposición a los rayos UV aumenta drásticamente. Ambos materiales ofrecen un buen rendimiento, pero el peso más ligero de la fibra de carbono (a menudo los postes para tiendas de trekking más ligeros del mercado) reduce la fatiga durante ascensos prolongados.

Degradación UV

La exposición prolongada al sol afecta de forma diferente a ambos materiales. La fibra de carbono muestra una degradación UV mínima, pero requiere revestimientos protectores. El aluminio desarrolla una oxidación superficial que en realidad protege el material del núcleo, por lo que requiere menos mantenimiento para un uso prolongado.

Comparación de resultados medioambientales

| Condición | Aluminio | Fibra de carbono | Norma de ensayo | Recomendación |

|---|---|---|---|---|

| Frío extremo | Excelente | Pobre | ASTM D746 | Aluminio polar/glacial |

| Exposición al agua salada | Bien | Feria | ISO 9227 | Preferiblemente aluminio anodizado |

| Gran altitud | Bien | Excelente | Pruebas sobre el terreno | Fibra de carbono para ahorrar peso |

| Calor del desierto | Excelente | Bien | MIL-STD-810 | Ambos adecuados |

| Resistencia UV | Bien | Excelente | ASTM G154 | Fibra de carbono con revestimiento |

Kelyland ofrece configuraciones de bastones de tienda de trekking específicas para cada clima, lo que ayuda a los distribuidores regionales a ofrecer soluciones óptimas. Para un rendimiento general, el aluminio sigue siendo la opción más versátil, mientras que la fibra de carbono brilla en condiciones específicas en las que el ahorro de peso es fundamental.

Matriz de decisiones: Adecuación del material del poste al perfil de la aventura

Elegir entre bastones de aluminio o fibra de carbono para tiendas de campaña de trekking depende en gran medida de su estilo de aventura. Esta guía te ayuda a adaptar los materiales de los bastones a actividades al aire libre específicas, para que obtengas el rendimiento adecuado a tus necesidades.

“Para los excursionistas, el ahorro de peso que ofrece la fibra de carbono justifica su coste, mientras que los campistas familiares se benefician de la durabilidad y la asequibilidad del aluminio”.”

Recomendaciones para senderistas ultraligeros

Para los excursionistas que recorren largas distancias por el PCT/AT, los postes de fibra de carbono para tiendas de campaña son ideales. Su ligereza (a menudo son los postes más ligeros disponibles para tiendas de campaña) reduce la fatiga durante los meses que dura la ruta. Las opciones de fibra de carbono de Kelyland incluyen puntas reforzadas para terrenos rocosos, habituales en estas rutas.

Idoneidad para acampar en familia

Los postes de aluminio para tiendas de campaña ofrecen la mejor relación calidad-precio para acampadas familiares. Su durabilidad resiste el montaje y desmontaje frecuentes y el manejo ocasionalmente brusco por parte de los niños. La aleación de aluminio 7001-T6 de Kelyland proporciona una excelente resistencia a un precio razonable.

Requisitos para el montañismo

Las expediciones a gran altitud exigen bastones de tienda de trekking fiables. Mientras que la fibra de carbono funciona para escaladas moderadas, el aluminio es preferible para condiciones extremas debido a su tolerancia a la temperatura. Kelyland ofrece bastones de aluminio para expediciones con mecanismos de bloqueo reforzados.

Opciones de personalización

Ambos materiales ofrecen personalización a través del proceso OEM de Kelyland. Elige entre empuñaduras de corcho o espuma, varios sistemas de ajuste de longitud y elementos de marca. La fibra de carbono permite un ajuste más preciso de la distribución del peso para aplicaciones de alto rendimiento.

Matriz de decisión del perfil de aventura

| Perfil del usuario | Material recomendado | Características principales | Opciones de Kelyland | Flexibilidad MOQ |

|---|---|---|---|---|

| Senderista | Fibra de carbono | Ultraligero, rígido | Puntas reforzadas | Más de 50 pares |

| Acampada familiar | Aluminio | Duradero y asequible | Aleación 7001-T6 | 25+ pares |

| Montañero | Aluminio | Resistente al frío | Calidad de expedición | Más de 100 pares |

| Mochilero de fin de semana | Ambas opciones | Características del saldo | Puños personalizados | Más de 50 pares |

| Equipador/Minorista | Ambas opciones | Mercado específico | Personalización total | Más de 500 pares |

Los postes para tiendas de campaña de trekking de Kelyland se adaptan a diversos perfiles de aventura gracias a la selección de materiales y la personalización. Tanto si necesita los postes de fibra de carbono más ligeros para senderismo como aluminio resistente para acampadas familiares, nuestro proceso OEM ofrece soluciones de calidad para empresas.

Conclusión

Tras años probando bastones en todo tipo de terrenos, desde tormentas desérticas hasta ventiscas alpinas, he aprendido que no existe el material perfecto, sino el adecuado para cada aventura. La fibra de carbono cambia las reglas del juego para los contadores de gramos, mientras que la fiabilidad del aluminio lo convierte en mi material preferido para terrenos impredecibles.

En Kelyland, hemos visto cómo esta elección afecta al rendimiento en el mundo real. Tanto si estás equipando a excursionistas como a campistas familiares, adaptar el material a la misión es más importante que las especificaciones sobre el papel. Por eso probamos cada lote nosotros mismos, para que obtengas bastones que rinden cuando hace falta.

La columna vertebral de tu tienda de campaña no debería ser algo secundario. Elige bien, y esos postes te llevarán a través de innumerables amaneceres.

PREGUNTAS FRECUENTES

-

P1: ¿Qué son las tiendas de campaña de varillas?

A1: Las tiendas de campaña con bastones de trekking utilizan los bastones de trekking existentes como estructura de soporte principal, lo que las hace ligeras y compactas. Son ideales para mochileros y excursionistas que buscan minimizar el peso del equipo sin renunciar a un refugio adecuado.

-

P2: ¿Son mejores las varillas de aluminio o las de fibra de carbono?

A2: Las varillas de aluminio son más resistentes y baratas, mientras que las de fibra de carbono ofrecen una mejor relación peso/resistencia, pero son más caras. La elección depende del presupuesto, el peso deseado y el uso previsto.

-

P3: ¿Cuánto pesan las tiendas de campaña de varillas?

A3: Las tiendas de campaña con pértiga pueden pesar tan sólo una libra, lo que las convierte en una excelente opción para quienes buscan minimizar el peso de su mochila. El peso exacto depende del modelo y de los materiales utilizados.

-

P4: ¿Cuál es la durabilidad de las tiendas de campaña de varillas de trekking?

A4: Las tiendas de campaña de varillas suelen ser duraderas, especialmente las fabricadas con tejidos de alta calidad resistentes al desgarro y a los elementos impermeables. Sin embargo el cuidado y el mantenimiento son cruciales para la longevidad.

-

P5: ¿Se puede montar una tienda de campaña de varillas de trekking sin varillas de trekking?

A5: Aunque las tiendas de campaña de trekking están diseñadas para montarse con bastones de trekking, muchas también pueden montarse con soportes alternativos, como árboles o un juego de bastones aparte, si es necesario.

-

P6: ¿Cuáles son las ventajas de utilizar tiendas de campaña de varillas de trekking?

A6: Entre sus ventajas se incluyen la reducción de peso al eliminar los bastones específicos para tiendas de campaña, la versatilidad, ya que los bastones de trekking son polivalentes, y unos costes a menudo inferiores en comparación con las tiendas tradicionales con sistemas de bastones independientes.

-

P7: ¿Cuál es el mejor caso de uso para las tiendas de campaña de varillas de trekking?

A7: Las tiendas de campaña con pértiga de trekking son las más adecuadas para el excursionismo ligero, los viajes con mochila y las actividades en las que es esencial minimizar el peso y el volumen del equipo, como el excursionismo de travesía.

-

P8: ¿Cómo elegir el mástil adecuado para una tienda de campaña de trekking?

A8: Ten en cuenta el material (aluminio frente a fibra de carbono), el peso, la resistencia y la compatibilidad con tu tienda de campaña. Busca un equilibrio entre opciones ligeras y duraderas en función de tus necesidades de trekking.

Enlaces externos

- Tiendas de campaña con bastones de trekking – Seek Outside

- Elegir el refugio adecuado: guía para excursionistas sobre los tipos de tiendas de campaña – Thruhiker

- Tiendas de campaña con bastones de trekking: ventajas y desventajas – SectionHiker

- Las mejores tiendas de campaña con pértiga para mochileros ligeros

- Durston | Palo de tienda Z-Flick

- Tiendas de campaña y accesorios Fortius Trekking Pole – OutdoorVitals

- El sueño de los excursionistas: más de 7 tiendas de campaña revolucionarias para bastones de trekking

- Las 10 mejores tiendas de campaña con bastones de trekking de 2025 – Pure Hiker