Backpack

Introduction

Backpacks are a must-have for any outdoor journey—combining utility, comfort, and durability into one essential item. At Kelyland Outdoors, we bring over 12 years of manufacturing and sourcing expertise to deliver a comprehensive range of backpacks for diverse outdoor needs. By working with reliable partner factories, we support B2B buyers with stable supply, flexible customization, and competitive pricing.

Our lineup includes compact belt bags and sling bags for everyday carry, cycling backpacks engineered for mobility and ventilation, and versatile daypacks for light travel or urban use. For more demanding adventures, we offer hiking backpacks with ergonomic support, tactical packs with modular compartments, and waterproof models for all-weather protection. Each is designed to serve different user groups—from casual explorers to seasoned outdoor professionals.

Materials are carefully selected for performance—featuring water-resistant fabrics, reinforced stitching, and padded back panels for all-day comfort. Volume options range from small 5L hydration packs to large-capacity 60L backpacks, and features like MOLLE systems, adjustable straps, and hydration compatibility add practical value to every design.

Kelyland Outdoors offers full OEM/ODM services, including logo printing, fabric color selection, and packaging customization. With low MOQs and end-to-end sourcing support, we help global wholesalers and retailers grow their brand with reliable, market-ready outdoor backpacks. Let’s work together to elevate your gear offerings and meet growing outdoor demand.

Product Collection

Check out our premium backpack lineup for your business

Get Your Custom Backpack Now !

Material Selection

Learn about our backpack material choices and functional accessories

Fabric Options

Oxford Fabric

A versatile, budget-friendly fabric woven from polyester or nylon. Known for its durability and cost-effectiveness, it offers decent abrasion resistance and is easy to coat for water repellency. Commonly used in backpacks, storage pockets, and organizer panels.

Polyester Fabric

Lightweight and UV-resistant, polyester fabric is widely used for daily backpacks and promotional bags. It offers excellent colorfastness and printability, making it ideal for custom branding. Durable and easy to maintain.

Ripstop Polyester Fabric

Woven with reinforced threads in a grid pattern, ripstop polyester resists tearing and ripping under stress. Lightweight yet tough, it is commonly used in lightweight backpacks and technical outdoor gear.

TPU Polyester Composite Fabric

A laminated fabric combining polyester with TPU film for enhanced waterproofing and durability. Seamless and flexible, it meets IPX standards and is ideal for waterproof packs and wet-condition outdoor bags.

Nylon Fabric

Strong, lightweight, and abrasion-resistant, nylon is a core material for outdoor and tactical packs. Typically used in 210D to 1000D ranges, it can be coated for water resistance and improved durability.

Ripstop Nylon Fabric

Engineered for strength, this fabric integrates ripstop weaving to prevent tearing. It maintains nylon’s toughness while reducing weight. Ideal for compact hiking packs and high-performance outdoor gear.

Cordura Nylon Fabric

A premium-grade nylon known for superior abrasion resistance and rugged durability. Used extensively in tactical, military, and high-end backpacks. Offers excellent strength-to-weight ratio and long lifespan.

TPU Nylon Composite Fabric

Combines robust nylon base with TPU coating for full waterproof performance. Features excellent elasticity, abrasion resistance, and cold-weather performance. Applied in dry bags and all-weather backpacks.

TPU Mesh Fabric

Mesh coated with TPU film to achieve semi-transparent waterproof structure. Used for exterior pouches and breathable compartments in waterproof backpacks. Balances ventilation and water protection.

PVC Mesh Fabric

Reinforced mesh infused with PVC coating. Durable, rigid, and waterproof, it’s ideal for external storage pockets or beach/wet-environment backpacks. Offers excellent structure and easy cleaning.

Canvas Fabric

Heavy-duty cotton or blended fabric with vintage aesthetics. Durable and abrasion-resistant, often used for lifestyle backpacks or retro-styled hiking bags. Needs additional coating for waterproofing.

Nylon-Spandex Stretch Fabric

Elastic fabric combining nylon and spandex, offering excellent stretch and flexibility. Used in compression pockets, bottle holders, and expandable compartments on backpacks. Lightweight and form-fitting.

Mesh Fabric

Breathable and lightweight, mesh fabric is commonly used in back panels, inner organizers, and pocket lining. Enhances ventilation and reduces moisture build-up in high-contact areas.

Stretch Mesh Fabric

An elastic version of standard mesh that expands to hold gear securely. Ideal for side pockets and front compartments on backpacks. Provides flexible storage without adding bulk.

Choose Your Preferred Backpack Fabric

Fabric Coating Options

Durable Water Repellent

DWR is a surface treatment that causes water to bead and roll off the fabric, rather than soak in. Commonly applied to polyester and nylon, it enhances light rain protection but may wear off over time. Ideal for casual backpacks and outer layer reinforcement.

PVC Coating

A thick, plasticized coating that makes fabrics fully waterproof and highly durable. Adds stiffness and weight, making it suitable for low-cost waterproof backpacks or gear for extreme wet conditions. Often used on Oxford and polyester fabrics.

PU Coating

A versatile, lightweight coating offering water resistance and added strength. PU coatings can be applied in single or multiple layers and are widely used on nylon, polyester, and Oxford fabrics. Common in hiking, commuter, and school backpacks.

TPU Coating

TPU coating delivers high-end waterproofing, abrasion resistance, and elasticity. Lighter and more flexible than PVC, it bonds well with nylon or polyester. Suitable for technical outdoor packs and waterproof backpacks that demand IPX-level protection.

Silicone Coating

Used primarily on nylon fabrics, silicone coating offers excellent waterproofing, UV resistance, and tear strength. It retains the fabric’s flexibility while drastically improving durability. Ideal for ultralight and technical outdoor gear such as hiking and trekking backpacks.

Choose Your Preferred Backpack Fabric Coating

Back System Options

Encased Mesh Fabric + Foam Panel

This structure features high-resilience PU foam padded with breathable mesh fabric, offering excellent comfort and sweat ventilation. Commonly used in daypacks, hiking backpacks, and cycling packs for lightweight back support with cushioning.

Metal Frame + PVC Woven Mesh Fabric

A lightweight steel or aluminum bar frame supports a tensioned PVC mesh panel. This provides firm structural support and ventilation. Mesh pattern, stiffness, and color are fully customizable. Ideal for technical hiking and tactical backpacks.

Metal Frame + PVC Woven Mesh Fabric + Foam Panel

Combines a tensioned mesh frame with a rebound foam base for enhanced comfort and load distribution. The bottom foam panel cushions the lower back. Suitable for high-load hiking or expedition backpacks needing both airflow and padding.

Detachable Support Frame

Features a removable internal frame composed of metal bars and PVC woven mesh. This offers customizable support based on user preference or load requirements. Typically used in modular hiking or tactical backpacks for flexible back support.

PU Rebound Foam

High-elasticity polyurethane foam provides consistent shape retention and pressure relief. Often inserted in back panels or shoulder straps for ergonomic comfort. Widely used in commuter, travel, and outdoor backpacks.

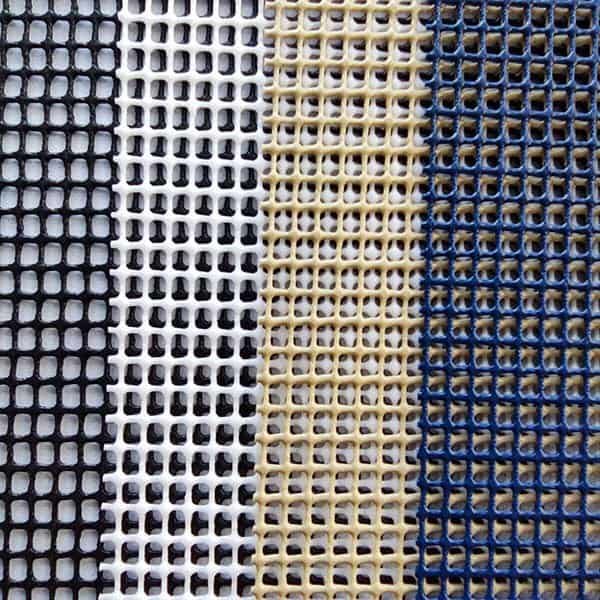

PVC Woven Mesh Fabric

The main material for breathable back panels. Available in multiple textures and densities, it offers durability, breathability, and easy customization. Frequently used in sports, tactical, and outdoor backpack designs.

Curved Metal Bar

Thin steel or aluminum rods are shaped and embedded in the back panel to create contour-fitting ergonomic support. These bars are often removable and help stabilize the load, especially in hiking and tactical backpacks.

Customize Your Ideal Back System

Accessory Options

Plastic Film

Transparent plastic films—mainly made of PVC or TPU—are used for waterproof compartments, ID windows, or interior sleeves. TPU variants offer greater flexibility and durability, ideal for outdoor or waterproof packs.

Plastic Plate

Typically made from PE or PET sheets, plastic plates are used as internal support layers in hip belt structures. They add rigidity and shape retention, enhancing load transfer and waist stability in ergonomic backpack designs.

Airtight Waterproof Zipper

These zippers provide IPX-level water resistance, ensuring full sealing against rain or submersion. Typically applied in waterproof backpacks and dry bags. Available in high-tension TPU or coated materials for outdoor use.

Nylon Zipper

Lightweight, smooth-operating zippers ideal for daypacks, school bags, or urban backpacks. Cost-effective and durable for general use.

Resin Zipper

Molded plastic zippers designed for heavy-duty use. Offer strong durability and water resistance, often found in hiking, tactical, or sports backpacks.

Metal Zipper

Known for strength and a premium appearance. Used in fashion, leather, or retro-style packs where aesthetics and durability matter.

Buckle Strap

Multi-functional strap with a plastic or metal buckle, stitched to backpack sides, bottom, or shoulder strap areas. It secures items like trekking poles, sleeping bags, or expands carrying capacity. Also used to connect dual straps across the chest for better load balance.

Webbing Clip

Quick-release plastic clips designed to fasten webbing ends, enabling adjustable length or modular configurations. Found in tactical packs or modular outdoor gear systems.

Elastic Cord Lock

Cord fastener system that secures elastic ropes used for attaching trekking poles, jackets, or external gear. Enhances expandability and load control.

Rain Cover

Protective backpack covers made of waterproof polyester or nylon, often with customizable logos. Optional silver or black PU coating enhances UV and rain protection. Essential for hiking, trekking, and travel packs.

Velcro

Hook-and-loop fasteners used for modular compartments, badge placement, or quick-access flaps. Ideal for tactical and utility packs that require flexible configuration.

Reflective Stripe

Safety-enhancing reflective strips stitched onto backpacks for visibility in low-light conditions. Common in cycling, running, and urban commuting bags.

Snap Button

Fasteners used in flap closures, pouches, or accessory attachments. Available in rust-resistant metal or lightweight plastic for various backpack styles.

Drip-Molded Rubber Patch

Rubber port covers or grommets used for headphone or charging cable pass-through. Combines protection and convenience for tech-integrated backpacks.

D-Ring

D-shaped attachment point made of metal or reinforced plastic. Used for hooking gear, keys, or tools externally. Common in tactical and adventure packs.

Grommet

Reinforced eyelets for ventilation, water drainage, or drawstring pass-through. Enhances durability at stress points in the fabric.

EVA Foam

A lightweight, shock-absorbing material used in backpack back panels, shoulder straps, and hip belt supports. It provides enhanced cushioning, stability, and ergonomic comfort for long-time wear.

EPE Foam

Expanded polyethylene foam used for moderate cushioning in laptop sleeves or inner dividers. Balances weight and protection with cost efficiency.

Customize Your Ideal Backpack

Manufacturing Process

Explore the precision process behind our backpack production

Step 1 - Product Design

Conceptualize the backpack's style, structure, and functionality. This stage includes sketching, 3D modeling, and material selection based on usage scenarios and target markets.

Step 2 - Pattern Making

Create precise paper or digital patterns for each backpack component. Patterns ensure consistency and guide cutting and assembly during production.

Step 3 - Material Incoming

Receive bulk materials including fabrics, webbings, zippers, buckles, foams, and frames. Materials are documented and stored according to specifications.

Step 4- Material Inspection

Perform quality checks on incoming materials for color accuracy, tensile strength, waterproof performance, and conformity to client standards. Defective batches are rejected or returned.

Step 5 - Fabric Cutting

Use manual or automatic cutting machines to slice fabrics according to pattern layouts. Accurate cutting minimizes waste and ensures uniformity.

Step 6 - Belt Cutting

Cut webbings, straps, and tapes into precise lengths. This step is critical for the consistency of shoulder straps, chest straps, and compression belts.

Step 7 - Gluing and Folding

Apply glue or heat-press treatment for edge reinforcement, decorative folding, or layer bonding. Especially used in pockets, bottom reinforcement, or leather-trimmed parts.

Step 8 - Sewing

Assemble the backpack by stitching all fabric components together, including main compartments, side pockets, and inner layers. Skilled workers ensure clean and durable seams.

Step 9 - Bartacking

Reinforce high-stress areas (e.g. strap joints, webbing ends) using bartack stitching machines. Enhances structural integrity and prolongs product lifespan.

Step 10 - Button Sewing

Sew on snap buttons or magnetic closures. This step includes precision placement and tightness adjustment to ensure smooth opening and secure closure.

Step 11 - Nailing

Apply metal rivets, D-rings, grommets, or logo plates using nailing machines. Adds functional and decorative elements.

Step 12 - Product Inspection

Conduct thorough inspections for sewing defects, missing parts, alignment issues, or functional flaws. Each unit is checked before packaging.

Step 13 - Product Testing

Perform in-house performance testing such as load-bearing strength, zipper durability, water resistance (if required), and visual aesthetics.

Step 14 - Packaging

Pack backpacks according to customer requirements—individually polybagged, labeled, and boxed for safe transportation. Custom packaging available on request.

Step 15 - Warehousing

Store finished goods in a clean, categorized warehouse awaiting shipment. Ensures efficient dispatch and order fulfillment.

Get More Details On Backpack Manufacturing Process

Customization Highlight

Personalize backpack to reflect your brand’s identity

Fabric Dyeing

Fabric color can be customized based on Pantone codes or sample swatches provided by the client. We ensure color consistency across bulk production.

Silk-Screen Printing

A traditional and cost-effective method for printing logos. Suitable for 1–4 colors and works well on flat fabric panels.

Digital Printing

Ideal for full-panel or large-surface graphic printing. High-resolution and vibrant images can be printed directly onto the fabric.

Thermal Transfer Printing

Suitable for complex or gradient-color logos. Transfers are heat-pressed for precise and durable application.

Water Transfer Printing

Commonly used for camo or full-wrap prints. Offers high coverage with detailed camouflage or texture effects.

Embroidery

Adds a premium, textured feel to the backpack. Commonly used for brand logos and emblems. Available in multi-color stitching.

Rubber Label

Soft-touch silicone or rubber logo patches. Offers a 3D effect with vibrant colors and waterproof durability.

Leather Label

Genuine or PU leather patches with laser-engraved or embossed logos. Suitable for vintage or premium styles.

Woven label

Custom woven fabric labels stitched onto the product. Often used on the inner back panel or front bottom edge.

Washing Label

Printed care and material information on non-woven fabric. Can include custom branding or QR codes if required.

Manual

Custom-printed user manuals or product care instructions can be included upon request.

Hang Tag

Custom tags with your logo, product info, and barcode. Options include paper, kraft, or coated finish.

Rain Cover

Can be made in custom colors, with logo or pattern printing. Optional silver/black PU coating available for UV and water protection.

Box

Export-grade cartons can be printed with your logo, brand message, or shipping details. Custom inner box packaging is also available.

Share Your Branding Needs With Us

Customer Reviews

Discover client testimonials on our backpacks and service

FAQs

Here you can find answers to the most common questions about sourcing and customizing our backpacks

Q1. Can I purchase your products if I’ve never done import business?

- Reply: Yes, whether you’re an individual or a company, we offer full sales support. Except in rare cases where governments require imports under a company name, we provide end-to-end services—from design and development to production, inspection, and door-to-door shipping—for all our partners.

Q2. Can you handle large orders for wholesalers?

- Reply: Absolutely. With a stable supply chain, nearly 20 core partner factories, and over 200 suppliers, we can meet the needs of small retailers, large wholesalers, and chain stores. Our team and factories have extensive experience serving overseas clients.

Q3. What international certifications do your products have?

- Reply: Most of our products meet CE and ASTM standards. If your market requires specific certifications, we can provide test samples and assist you in obtaining the necessary approvals.

Q4. What is the typical process for purchasing your products?

- Reply:

- Contact our sales team, and we’ll evaluate your project based on your needs. You can also learn more about us via video calls, virtual factory tours, on-site visits, or third-party audits.

- After approval, we’ll design products or recommend options based on your requirements.

- Once you confirm the design, we provide a quote with detailed product specs.

- After agreeing on price and lead time, we’ll send a Proforma Invoice (PI) for sample confirmation if needed. You pay the sample fee, and we produce it within 7-15 days, contacting you if adjustments are required.

- We’ll share photos/videos of the sample for approval. If confirmed, we ship it via courier. If changes are needed, we refine it until you’re satisfied.

- After testing the sample, you approve bulk production. We send a bulk PI (or you send a PO after we update pricing and lead time).

- Once order details are finalized, you pay the deposit per agreed terms.

- Production starts after we receive the deposit. We’ll update you with progress, photos, or videos. Packaging is designed and produced during this time.

- 7-10 days before completion, we notify you for inspection (on-site or self-inspection reports provided). If issues arise, we resolve them until you’re satisfied.

- Before shipping, you pay the balance (or per agreed terms for long-term clients).

- After payment, we arrange shipping (your forwarder or ours). If we handle it, shipping costs are paid with the balance.

- We track the shipment and provide updates until you receive the goods. We can assist with import procedures if needed.

- Post-delivery, we offer after-sales support for quality issues to ensure your business runs smoothly.

Q5. Can you provide samples before a bulk order?

- Reply: Yes, we offer paid samples, with fees refundable upon bulk order confirmation (depending on the case). For low-cost samples, we can provide them free if you cover shipping.

Q6. What is the minimum order quantity (MOQ)?

- Reply: MOQ varies by product. Some specific items start at 50-100 pieces, while standard models range from 300-1,000 pieces. For bulk orders, we can adjust flexibly. Contact our team for an exact quote based on your needs.

Q7. How long does production take?

- Reply: Our standard production time is 30-45 days, depending on order timing, product type, quantity, and customization complexity.

Q8. Can you customize products with our logo or design?

- Reply: Yes, our core business is helping clients customize products and add their branding in various forms. This supports your unique brand promotion and sales.

Q9. Do you offer packaging customization, like branded tags or logo printing?

- Reply: Yes, our professional design team can create packaging drafts, discuss options with you, and finalize the best solution for your finished products.

Q10. What are the shipping costs and times from China?

- Reply: Costs depend on order volume and destination. We work with trusted logistics partners and can provide up-to-date quotes for sea, air, road, rail, or combined shipping options.

Q11. Can you provide logistics and transportation services?

- Reply: Yes, as a one-stop service provider, we offer door-to-door logistics if you cover the costs. We’ll recommend multiple shipping options for you to choose from.

Q12. Can you assist with import documents?

- Reply: Yes, we handle export paperwork and guide you through customs processes. Our experience ensures compliance with various market requirements.

Q13. What is your payment policy?

- Reply: For new clients or orders over US$3,000, we require a 30% deposit and 70% before shipment. For repeat clients or large orders, terms are negotiable.

Q14. How do you ensure quality control?

- Reply: Our factories follow ISO 9001:2015 standards, with inspections at every production stage. Reports are available upon request.

Q15. What maintenance or care do your products require?

- Reply: Our textile and metal products need no special upkeep. Just follow the user manual or our sales team’s guidance. Contact us if you have questions.

Q16. What is your warranty or return policy?

- Reply: We offer at least a 1-year warranty for manufacturing defects, with returns handled case-by-case.

Case Studies

Explore how we’ve tailored solutions for our backpack clients’ unique needs

Ready To Be Our Business Partner?

Get in touch and boost your business

Expand your product line with premium outdoor gear backed by 12 years of expertise. We help your business grow with custom designs, reliable production, and global logistics. Partner with us for seamless service and innovative solutions. Share your needs, and let’s create something great together!