Camp Kitchen

Introduction

Camp kitchen gear plays a vital role in enhancing outdoor cooking experiences, and at Kelyland Outdoors, it’s one of our most developed product lines. With over a decade of experience, we supply a comprehensive range of portable cooking solutions trusted by wholesalers and importers across the globe. Working closely with multiple reliable factories, we deliver thousands of units annually to meet varying customer demands.

Our camp kitchen lineup covers everything from compact mini stoves for backpackers to full-sized portable camping stoves for families and glamping setups. We offer charcoal grills made from stainless steel and carbon steel for traditional fire cooking, along with wood stoves featuring reinforced glass for scenic outdoor use. Lightweight cookware and utensils—crafted from aluminum, stainless steel, and titanium—ensure durability without sacrificing portability. Tableware options such as folding cups, bowls, and plates are designed for space-saving efficiency and ease of use in any setting.

To meet broader culinary needs, we also offer butane torches—compact, refillable, and compatible with standard canisters—perfect for flame-searing or ignition in outdoor conditions. For added versatility and safety, our silicone kitchenware selection includes collapsible bowls, ladles, spatulas, and other heat-resistant tools. These food-grade items are easy to clean, lightweight, and ideal for both camping and RV kitchens.

Whether your customers are preparing a quick meal on the trail or hosting a gourmet cookout under the stars, our products are built to perform in a wide range of outdoor environments. Many items come with foldable or nesting designs, making them ideal for backpacking, car camping, or luxury glamping setups. Material choices meet international food safety standards, ensuring confidence and safety for end users.

At Kelyland Outdoors, we support full customization. From branded prints and color options to tailored packaging and logo applications, our OEM services and flexible MOQs make it easy for businesses to create a unique product line. Let us help you streamline your sourcing and supply high-quality, market-ready camp kitchen gear. Reach out to explore how we can power your outdoor product offerings.

Product Collection

Check out our premium camp kitchen gear lineup for your business

Get Your Custom Camp Kitchen Gear Now !

Material Selection

Learn about our camp kitchen gear material choices and functional accessories

Metal Options

Cold-Rolled Steel (SPCC)

Cold-rolled steel offers excellent structural strength and dimensional accuracy, making it ideal for camping grills and stove frames. Though heavier than other metals, it is cost-effective and suitable for powder coating. Often used in carbon steel products, it's perfect for budget-friendly yet durable outdoor cooking gear.

Stainless Steel

Stainless steel provides superior corrosion resistance and food-grade safety, especially in 304 or 430 variants. It’s widely used in cookware, grills, and utensils due to its hygienic surface, heat resistance, and ease of cleaning. Stainless steel ensures long-term performance in rugged outdoor environments with minimal maintenance.

Aluminum

Aluminum is lightweight, rust-resistant, and an excellent heat conductor—perfect for camping cookware, kettles, and portable stoves. Its low density helps reduce pack weight, while anodized or hard-coated finishes enhance durability. Aluminum balances strength and portability, making it a favorite for both backpackers and car campers.

Titanium

Titanium is ultra-light, extremely strong, and naturally resistant to rust and corrosion. It’s non-toxic, leaves no metallic taste, and performs well in high-heat environments. Though more expensive, it’s ideal for premium camping cookware and utensils where weight reduction and top-tier performance are critical.

Choose Your Preferred Material To Make Camp Kitchen Gear

Surface Treatment Options

Powder Spraying

Powder spraying is a dry finishing process where powdered paint is electrostatically applied and cured under heat. It forms a tough, protective layer commonly used on steel parts of camping grills, stoves, and cooking stands. This coating resists rust, scratches, and heat, ensuring long-lasting outdoor performance in harsh environments.

Matte

Matte finishes reduce glare and give a refined, non-reflective surface ideal for minimalist cookware and utensils. It hides fingerprints and scratches, maintaining a clean look even after heavy use. Often applied to stainless steel or aluminum, it provides a premium, understated aesthetic for outdoor gear.

Mirror Polishing

Mirror polishing creates a highly reflective, smooth surface typically used on stainless steel tableware and utensils. It enhances appearance and hygiene by minimizing surface pores, making cleaning easier. This finish adds a premium touch and is especially suitable for glamping-grade cookware and kitchen accessories.

Brushed Finish

Brushed finishes feature fine linear textures, reducing surface reflection while maintaining a modern aesthetic. Commonly used on stainless steel and titanium cookware, it offers scratch resistance and improves grip. It's ideal for products requiring both style and durability, such as utensils and stove bodies.

Anodic Oxidation

Anodic oxidation is commonly applied to aluminum cookware and kettles, increasing surface hardness and corrosion resistance. It allows for color customization while retaining a food-safe, non-reactive finish. This treatment is lightweight and ideal for high-performance backpacking cookware and compact camp kitchen sets.

Chemical Etching

Chemical etching uses controlled acid reactions to create custom surface patterns, logos, or measurements on metal cookware and utensils. It’s a precise, non-mechanical method that maintains structural integrity. This process is popular for branding or adding functional marks without compromising hygiene or durability.

Embossing

Embossing creates raised patterns or logos by pressing into metal surfaces. It’s often used for branding on cookware, utensils, or stove plates. This process adds a tactile and visual identity to the product while withstanding repeated use, cleaning, and outdoor conditions without fading.

Spray Painting

Spray painting offers vibrant, customizable finishes for metal surfaces like stove panels or steel accessories. While not as durable as powder coating, it allows for detailed designs or small-batch customization. A clear topcoat is usually applied for added protection against wear and weather.

Titanium Crystal Ice Oxidation

Titanium crystal ice oxidation creates a unique shimmering effect with multi-tone color shifts, often used on high-end titanium cookware. This process is not just decorative—it also enhances surface hardness and corrosion resistance. It's ideal for ultralight luxury camping gear seeking both performance and visual appeal.

Teflon Coating

Teflon coating delivers excellent non-stick performance, making it ideal for frying pans and cooking pots. It ensures easy food release and minimal cleanup while resisting heat and abrasion. Commonly used in aluminum or stainless steel cookware, it enhances convenience for outdoor cooking in remote locations.

Titanium Plating

Plastic tableware is lightweight, durable, and easy to clean, making it ideal for outdoor use. It can be paired with metal cookware sets to complete a functional camping dining kit. Available in various colors and shapes, it's perfect for family camping, picnics, or backpacking trips.

Customize Your Ideal Surface Treatment

Accessory Options

Plastic Tableware

Plastic tableware is lightweight, durable, and easy to clean, making it ideal for outdoor use. It can be paired with metal cookware sets to complete a functional camping dining kit. Available in various colors and shapes, it's perfect for family camping, picnics, or backpacking trips.

Silicone Kitchenware

Made from food-grade silicone, these kitchen tools are flexible, heat-resistant, and collapsible for easy packing. Their excellent insulation properties protect hands from hot surfaces. Ideal for outdoor cooking, they include bowls, ladles, and spatulas designed for convenience and space-saving portability.

Plastic Components

Plastic components are used in handles, knobs, connectors, and other structural parts across camping kitchen gear. These can be color-customized to match brand identity. Injection-molded from durable materials, they offer reliable strength, lightweight properties, and UV resistance for long-term outdoor usage.

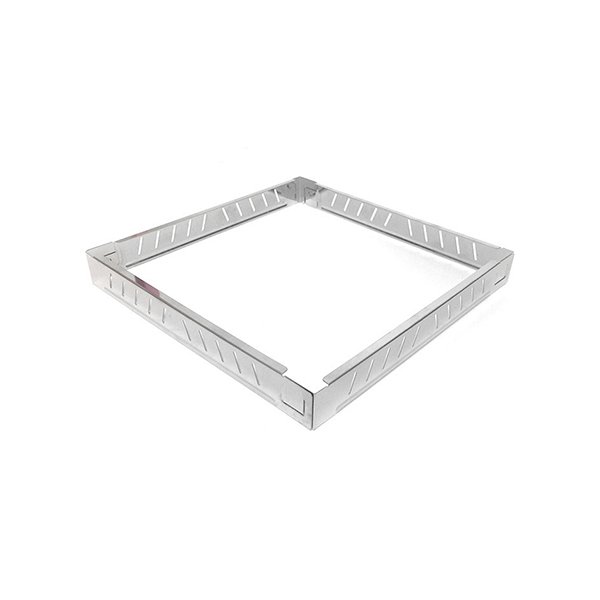

Heat-Concentrating Ring Structure

This ring design is integrated into the base of camping kettles and pots to improve fuel efficiency. It directs and concentrates heat under the cookware, reducing boiling time and conserving gas. It's especially valuable for high-altitude or cold-weather use, enhancing performance in rugged outdoor environments.

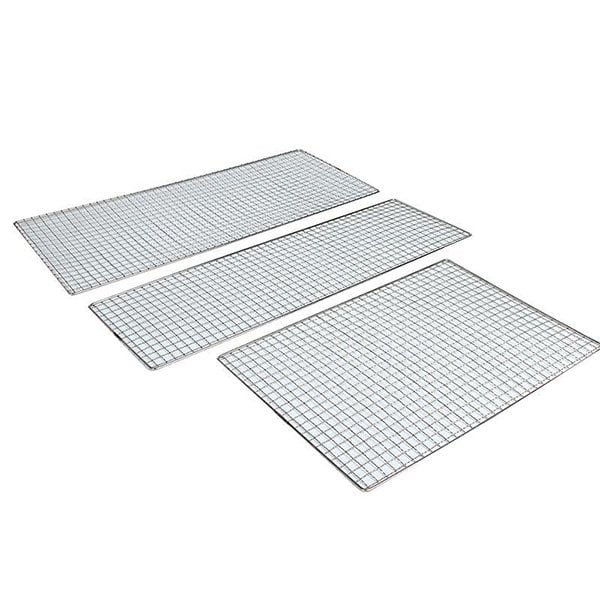

Grill Grate

Grill grates are essential components for charcoal grills, made of stainless steel or coated steel. They provide even heat distribution and support direct cooking of meat and vegetables. Easy to clean and rust-resistant, they’re designed for portability and quick setup during outdoor barbecues.

Stove Chimney Pipe

A crucial part of any wood-burning stove system, the chimney pipe vents smoke safely while maintaining strong airflow. Typically made from stainless or carbon steel, it supports efficient combustion and heat output. Easy to assemble, it ensures safer operation in tents or shelters during cold-weather camping.

Schott Fire-Resistant Glass

This premium glass panel, used in some wood stoves, allows clear viewing of the fire while offering extreme heat resistance. Made by Schott, it’s scratch-resistant and thermally stable, adding a luxury touch and practical fire-monitoring function to your high-end camping stove setup.

High-Output Stove Burner

This powerful burner module enhances the performance of camping stoves, delivering rapid heat for fast cooking. Designed for wind resistance and high thermal efficiency, it's ideal for boiling water or frying in outdoor conditions. A great upgrade for users seeking faster meals while camping.

Dual-Mode Fuel System

This system allows the stove to operate with two types of fuel, such as butane and propane. It offers flexibility for different regions and availability, making the stove more versatile and convenient. Ideal for international camping trips or emergency preparedness where fuel choice is uncertain.

Gas Canister Adapter

This adapter connects various gas canisters to compatible stove models, expanding the usability of camping stoves. It ensures stable gas flow and leak-free performance. Lightweight and compact, it’s an essential tool for multi-day hikes or travel across regions with differing fuel standards.

Wind Deflector

A foldable metal screen placed around the stove setup, the wind shield minimizes wind interference during cooking. Essential for mini or camping stoves, it improves heat retention and fuel economy. Lightweight and packable, it’s perfect for backpackers and mobile campers cooking in open areas.

Wind Shield

Attached directly to stove heads, this metal ring shields the flame from wind, ensuring consistent cooking even in breezy outdoor environments. It boosts fuel efficiency and safety by maintaining a stable flame. Compact and detachable, it’s a practical addition to portable stoves.

Mesh Bag

Made of durable mesh fabric, this drawstring bag is used to store and carry camping tableware, cookware, and utensils. It allows for ventilation and quick drying after washing. Transparent design makes gear easy to identify, while compact size helps with organized packing.

Storage Bag

Designed to hold larger sets of camping kitchen equipment, this bag features compartments, zippers, and reinforced handles. It accommodates cookware, stoves, or utensil sets, keeping everything organized and protected. Often made of waterproof fabric, it's built for heavy-duty outdoor transport.

Plastic Suitcase

This hard-shell plastic suitcase is designed to store and protect camping stoves. It offers secure latch closures, internal padding, and carry handles for safe and convenient transport. Resistant to impact and weather, it keeps gear in top condition during travel or storage.

Plastic Box

Compact and impact-resistant, this plastic box is tailored for mini stove storage. It shields the stove from dust, moisture, and physical damage. The snap-lock lid ensures secure closure, while its stackable design helps with efficient storage and transport for frequent outdoor users.

Customize Your Ideal Camp Kitchen Gear

Manufacturing Process

Explore the precision process behind our camp kitchen gear production

Step 1 - Product Design

Our R&D team designs each item—whether it’s a portable stove, titanium cookware, or folding kettle—based on ergonomic performance, outdoor durability, and market feedback. We focus on foldability, weight reduction, and heat efficiency to meet the diverse needs of campers, backpackers, and glamping users.

Step 2 - Material Incoming

We source high-grade raw materials such as cold-rolled steel, 304 stainless steel, aluminum, titanium, and food-grade silicone. Incoming materials for cookware, stoves, utensils, and tableware are inspected and stored separately to ensure stable production supply for various camping kitchen product lines.

Step 3 - Material Inspection

All metals undergo thickness, hardness, and corrosion resistance checks, including salt spray tests. Silicone and plastic parts are tested for food safety and durability. This process ensures that products like stoves, cookware, and folding cups meet strict quality requirements for outdoor use.

Step 4 - Plastic Injection

We use precision injection molding to produce components such as stove knobs, utensil handles, folding cup parts, and storage box accessories. The color of plastic parts can be customized according to OEM requests, providing branding flexibility for customers.

Step 5 - Metal Laser Cutting

We use precision laser cutting to shape aluminum, titanium, and stainless steel sheets into cookware, stove panels, and utensils. This process ensures clean edges, accurate dimensions, and minimal material distortion—crucial for components like titanium bowls, aluminum bases, and stainless wind shields.

Step 6 - Forging

Cookware items like frying pans, kettles, and stove burner components are forged to shape using precision dies and heat processes. This enhances their structural strength and durability—especially important for titanium and aluminum-based outdoor products exposed to high heat and rugged use.

Step 7 - Forming

Using hydraulic presses or forming dies, we shape metal sheets into finished forms—e.g., deep-drawn cookware, stove fuel chambers, or wind shields. This ensures precise curves, safe edges, and structural consistency across high-volume production runs.

Step 8 - Punching

Mounting holes, ventilation slots, or assembly grooves are created in stove panels, grill bases, and cookware handles. CNC punching machines ensure dimensional accuracy, enabling easy part connection and effective airflow control in combustion systems.

Step 9 - Welding

Manual or robotic welding joins critical parts in charcoal grills, stove bodies, and wood stoves. High-strength welding is vital for structural reliability during outdoor use, particularly in components like chimney pipes and fuel chambers that experience direct heat exposure.

Step 10 - Powder Spraying

Cold-rolled steel stoves and charcoal grills are powder-coated for corrosion resistance and surface durability. We offer matte, glossy, or textured finishes in custom colors to match brand identity while providing protection against high temperatures and outdoor conditions.

Step 11 - Polishing

Stainless steel and titanium items such as utensils, tableware, and kettle surfaces are polished for smoothness and aesthetics. Mirror, matte, or brushed finishes enhance appearance and offer options tailored for high-end camping or glamping applications.

Step 12 - Silk-Screen Printing

For clients who require branded cookware or utensils, we apply one-color or multicolor silk-screen printing of logos or graphics. This adds value to items like folding bowls, plates, and stainless steel mugs, reinforcing brand recognition on functional surfaces.

Step 13 - Laser Marking

Laser engraving is used for permanent branding on metallic parts such as knives, titanium utensils, or stove panels. It is precise, durable, and resistant to wear, making it ideal for high-end customizations and OEM branding.

Step 14 - Assembly

Final assembly involves integrating stove parts, installing valves, mounting folding handles on cookware, and inserting mesh bags into carry kits. All products undergo strict QC during this stage to ensure secure fitting, usability, and compliance with client specifications.

Step 15 - Product Testing

We conduct flame tests, stability tests, fuel efficiency assessments, and cookware thermal performance checks. For food-contact items, safety compliance and weight tests are done. This guarantees that each camping kitchen product performs reliably in real outdoor environments.

Step 16 - Packaging

Products are packed in branded boxes, carry bags, or plastic cases based on client requirements. Packaging protects the products and enhances presentation in retail or wholesale settings. Custom printing, barcoding, and instruction inserts are available to meet export standards.

Step 17 - Warehousing

Finished goods are stored in organized warehouses with SKU management for efficient delivery. Inventory is separated by product category—stoves, cookware sets, utensil kits—allowing us to handle bulk orders, quick shipments, and mixed container loads with precision.

Get More Details On Camp Kitchen Manufacturing Process

Customization Highlight

Personalize camp kitchen gear to reflect your brand’s identity

Silk-Screen Printing

This method allows single or multi-color logos to be printed directly onto cookware, stove bodies, or utensil handles. Ideal for flat or slightly curved surfaces, it’s a cost-effective branding solution for stainless steel or aluminum kitchenware.

Thermal transfer printing

Used for full-color or complex patterns, thermal transfer is perfect for branding plastic or coated surfaces like carry bags or plastic suitcases. It offers higher resolution and durability than silk-screen, suitable for detailed logo or artwork presentation.

Laser Marking

Laser marking applies permanent, high-precision logos or codes on stainless steel, aluminum, or titanium parts. It’s ideal for cookware, utensils, or burner heads where heat resistance and long-lasting branding are critical.

Laser Cutting

Custom logos or vent designs can be laser-cut into metal stove bodies, wind shields, or grates. This method is both decorative and functional, adding airflow control or visual distinction while reinforcing brand identity.

Embossing

Used for stamping brand logos or patterns into stainless steel or titanium cookware and utensils. Embossing offers a subtle, high-end look without affecting surface coating or durability. Common for lids, pot bases, or metal trays.

Sticker

Printed stickers offer a flexible branding solution on flat plastic, metal, or packaging surfaces. They are commonly used for temporary identification, user instructions, or visual branding on stoves, utensil sets, or plastic boxes.

Metal Plate

Customized aluminum or stainless steel brand plates can be riveted or sewn onto stove bodies, cookware, or carry bags. This premium branding option enhances product perception, offering a professional, durable, and permanent identity tag.

Hang Tag

Hang tags are paper tags tied to cookware or packed accessories. They typically include branding, product details, or QR codes for marketing. A good low-cost option for increasing shelf presence and brand recognition.

Manual

Printed instruction manuals are customized with brand elements, safety guidelines, and usage instructions. Commonly included with camping stoves, wood stoves, or utensil kits, ensuring clear user guidance and improving perceived product value.

Plastic Box

Plastic boxes provide durable, stackable storage and branding opportunities for mini stoves, utensil sets, or stove accessories. Logos or labels can be printed or molded on the surface for a customized retail or OEM experience.

Carry Bag

Customized carry bags are made from nylon, Oxford fabric, or polyester, used for storing cookware sets, stoves, or grill kits. They can feature screen-printed or stitched logos, offering both functionality and brand visibility.

Color Box

Branded color boxes are ideal for retail presentation. Printed with logos, lifestyle images, and product information, they enhance shelf appeal and customer perception. Suitable for stove kits, cookware sets, or utensil combinations.

Master Carton

Master cartons are large shipping boxes that hold multiple retail units. Custom printing with brand logo, shipping instructions, and barcodes ensures professional packaging for bulk distribution and inventory management.

Share Your Branding Needs With Us

Customer Reviews

Discover client testimonials on our camp kitchen gear and service

FAQs

Here you can find answers to the most common questions about sourcing and customizing our camp kitchen gear

Q1. Can I purchase your products if I’ve never done import business?

- Reply: Yes, whether you’re an individual or a company, we offer full sales support. Except in rare cases where governments require imports under a company name, we provide end-to-end services—from design and development to production, inspection, and door-to-door shipping—for all our partners.

Q2. Can you handle large orders for wholesalers?

- Reply: Absolutely. With a stable supply chain, nearly 20 core partner factories, and over 200 suppliers, we can meet the needs of small retailers, large wholesalers, and chain stores. Our team and factories have extensive experience serving overseas clients.

Q3. What international certifications do your products have?

- Reply: Most of our products meet CE and ASTM standards. If your market requires specific certifications, we can provide test samples and assist you in obtaining the necessary approvals.

Q4. What is the typical process for purchasing your products?

- Reply:

- Contact our sales team, and we’ll evaluate your project based on your needs. You can also learn more about us via video calls, virtual factory tours, on-site visits, or third-party audits.

- After approval, we’ll design products or recommend options based on your requirements.

- Once you confirm the design, we provide a quote with detailed product specs.

- After agreeing on price and lead time, we’ll send a Proforma Invoice (PI) for sample confirmation if needed. You pay the sample fee, and we produce it within 7-15 days, contacting you if adjustments are required.

- We’ll share photos/videos of the sample for approval. If confirmed, we ship it via courier. If changes are needed, we refine it until you’re satisfied.

- After testing the sample, you approve bulk production. We send a bulk PI (or you send a PO after we update pricing and lead time).

- Once order details are finalized, you pay the deposit per agreed terms.

- Production starts after we receive the deposit. We’ll update you with progress, photos, or videos. Packaging is designed and produced during this time.

- 7-10 days before completion, we notify you for inspection (on-site or self-inspection reports provided). If issues arise, we resolve them until you’re satisfied.

- Before shipping, you pay the balance (or per agreed terms for long-term clients).

- After payment, we arrange shipping (your forwarder or ours). If we handle it, shipping costs are paid with the balance.

- We track the shipment and provide updates until you receive the goods. We can assist with import procedures if needed.

- Post-delivery, we offer after-sales support for quality issues to ensure your business runs smoothly.

Q5. Can you provide samples before a bulk order?

- Reply: Yes, we offer paid samples, with fees refundable upon bulk order confirmation (depending on the case). For low-cost samples, we can provide them free if you cover shipping.

Q6. What is the minimum order quantity (MOQ)?

- Reply: MOQ varies by product. Some specific items start at 50-100 pieces, while standard models range from 300-1,000 pieces. For bulk orders, we can adjust flexibly. Contact our team for an exact quote based on your needs.

Q7. How long does production take?

- Reply: Our standard production time is 30-45 days, depending on order timing, product type, quantity, and customization complexity.

Q8. Can you customize products with our logo or design?

- Reply: Yes, our core business is helping clients customize products and add their branding in various forms. This supports your unique brand promotion and sales.

Q9. Do you offer packaging customization, like branded tags or logo printing?

- Reply: Yes, our professional design team can create packaging drafts, discuss options with you, and finalize the best solution for your finished products.

Q10. What are the shipping costs and times from China?

- Reply: Costs depend on order volume and destination. We work with trusted logistics partners and can provide up-to-date quotes for sea, air, road, rail, or combined shipping options.

Q11. Can you provide logistics and transportation services?

- Reply: Yes, as a one-stop service provider, we offer door-to-door logistics if you cover the costs. We’ll recommend multiple shipping options for you to choose from.

Q12. Can you assist with import documents?

- Reply: Yes, we handle export paperwork and guide you through customs processes. Our experience ensures compliance with various market requirements.

Q13. What is your payment policy?

- Reply: For new clients or orders over US$3,000, we require a 30% deposit and 70% before shipment. For repeat clients or large orders, terms are negotiable.

Q14. How do you ensure quality control?

- Reply: Our factories follow ISO 9001:2015 standards, with inspections at every production stage. Reports are available upon request.

Q15. What maintenance or care do your products require?

- Reply: Our textile and metal products need no special upkeep. Just follow the user manual or our sales team’s guidance. Contact us if you have questions.

Q16. What is your warranty or return policy?

- Reply: We offer at least a 1-year warranty for manufacturing defects, with returns handled case-by-case.

Case Studies

Explore how we’ve tailored solutions for our camp kitchen gear clients’ unique needs

Ready To Be Our Business Partner?

Get in touch and boost your business

Expand your product line with premium outdoor gear backed by 12 years of expertise. We help your business grow with custom designs, reliable production, and global logistics. Partner with us for seamless service and innovative solutions. Share your needs, and let’s create something great together!