Folding Wagon

Introduction

Folding wagon is one of the most versatile transport tools in outdoor settings, and at Kelyland Outdoors, it’s a rising star in our product line. With over 12 years of manufacturing and customization experience, we develop and supply a wide range of collapsible wagons designed to meet the practical and branding needs of B2B clients worldwide.

Our lineup includes single-fold and multi-fold collapsible wagons, ideal for compact storage and quick deployment; double decker and extended folding wagons, engineered for maximizing storage space; and raised folding wagons with breathable mesh or oxford fabric extensions. For heavy-duty use, our utility folding wagons offer enhanced features like canopy shading, reclining structure, and all-terrain functionality—making them a perfect all-in-one mobile solution for outdoor events, camping trips, or beach days.

Built for durability and load-bearing, our wagons commonly use 600D double-layer oxford fabric with waterproof coatings, supported by 22mm+ aluminum alloy or powder-coated steel frames. Options include brake-equipped all-terrain wheels, extendable pull handles (62–105 cm), flip-down tailgates for loading long gear, and removable tabletops. Load capacities range from 50–200kg, and capacities from 90L to over 200L, depending on model and configuration.

At Kelyland Outdoors, we offer full OEM support, with customizable colors, logos, structures, and accessories. Our one-stop sourcing and low MOQs make us an ideal manufacturing partner for importers and brand owners looking to expand their outdoor product line. Reach out and discover how our folding wagons can elevate your business offering.

Product Collection

Check out our premium folding wagon lineup for your business

Get Your Custom Folding Wagon Now !

Material Selection

Learn about our folding wagon material choices and functional accessories

Fabric Options

Oxford Fabric

600D double-layer Oxford fabric is the most commonly used material for folding wagons. It features PVC, PU, or PE coatings for enhanced water resistance, tear strength, and durability. Ideal for heavy-duty usage, it supports high load capacity and maintains structural integrity under outdoor conditions.

Polyester Mesh Fabric

Lightweight and breathable, polyester mesh fabric is often used on the side storage pockets of folding wagons. It allows for ventilation while keeping small items accessible and secure. Though not load-bearing, it’s an excellent functional addition for added convenience and organization.

Choose Your Preferred Material To Make Folding Wagons

Frame Options

Round Metal Tube

Made of aluminum alloy or powder-coated carbon steel, round metal tubes are typically used at the four corner support rods of multi-fold wagons and as the main handle structure. They provide excellent load-bearing strength, are lightweight, and support smooth folding and unfolding mechanisms.

Square Metal Tube

Square tubes, usually made from aluminum or carbon steel, are commonly applied to the front and rear structural frames of single-fold wagons. Their flat surface offers greater stability and easier assembly alignment. These tubes are ideal for supporting large loads while maintaining a compact folded shape.

Oval Metal Tube

Oval metal tubes are used for side frame reinforcement and in pull handles, offering a sleek design and ergonomic grip. They help connect various structural elements and are favored for both strength and aesthetics. Aluminum and coated steel options are available to suit different performance and weight requirements.

Wheel Options

PP and PVC Wheel

This is the most cost-effective wheel option. The hub is made from durable polypropylene (PP), while the tire surface is PVC. Typically used for narrow wheels, this combination offers basic load support and is suitable for flat terrain with minimal shock absorption or noise reduction.

PP and PU Wheel

The wheel hub is constructed from strong PP, while the outer tire is made of PU foam. PU provides better cushioning and wear resistance compared to PVC. This type of wheel offers smooth rolling, better shock absorption, and quiet performance—ideal for both indoor and outdoor terrain.

PP and EVA Wheel

With a PP hub and EVA foam tire, this wheel offers lightweight performance and good flexibility. EVA is softer than PU and helps absorb impact, though it’s less wear-resistant. This wheel type is often chosen for its quiet rolling and suitability for soft surfaces like grass or sand.

PP and TPE Wheel

This wheel features a PP hub and TPE (thermoplastic elastomer) tire. TPE offers excellent elasticity, grip, and durability. Compared to EVA or PVC, TPE provides superior traction and shock absorption, making it suitable for more rugged surfaces or off-road folding wagon applications.

Accessory Options

Plastic Components

Injection-molded plastic parts are used to connect and support key frame areas. These components are durable, lightweight, and customizable in color to match different product designs, enhancing both function and visual appeal of the folding wagon.

Polypropylene Board

PP board is a lightweight, water-resistant material used as an internal layer for the folding baseplate. Sewn inside the fabric base, it helps reinforce the wagon structure while keeping the overall weight low for easy transport and folding.

MDF Board

MDF (Medium-Density Fiberboard) is another baseboard option, offering excellent rigidity and flatness. It’s commonly used in standard or heavy-duty wagons, sewn into the fabric base to provide stable and balanced support for loading gear.

Expanded Polyethylene Foam

Used as padding between wagon fabrics, EPE foam offers softness, cushioning, and shock absorption. It helps protect fragile items during transportation and adds comfort when wagons are used in bench or cot modes.

360° Rotating Wheels with Foot Brake

Swivel wheels with integrated brakes allow full directional control and secure positioning. Ideal for uneven terrain or sloped surfaces, this system ensures your wagon can be safely locked in place when stationary.

Side Pockets

Attached to the outer sidewalls, these fabric or mesh pockets offer additional storage space for tools, drinks, and small gear. They enhance functionality without affecting foldability, making them a popular add-on for users who need easy access to accessories.

Detachable Wheel

Designed for compact storage, detachable wheels allow the folding wagon to collapse into a smaller footprint. Users can easily remove wheels after use to save trunk space or for cleaning and maintenance purposes.

Camping Cot Style

A patented design that allows all four sides of the wagon to fold down, transforming it into a flat surface usable as a camping cot. This dual-use structure enhances product versatility and appeals to minimalist outdoor users.

Folding Bench Style

By folding one side and keeping the opposite side upright as a backrest, the wagon transforms into a functional bench. This space-saving solution is ideal for resting in outdoor settings like campsites, parks, or festivals.

Self-Retracting Telescopic Handle

This handle features a spring-loaded mechanism allowing automatic return up to 90 degrees. It can be extended and locked to a desired length, providing comfortable pulling and quick retraction for storage efficiency.

Damping-Controlled Telescoping Handle

Unlike spring-loaded handles, this version uses a damping system to adjust and fix angles smoothly. It prevents auto-retraction, offering more stable positioning and flexibility when pulling or pushing the wagon on varied terrain.

Removable Camping Cart Cover

The wagon’s outer fabric body can be detached from the metal frame, making it easier to clean or replace. This design increases hygiene and allows customization for different branding or seasonal patterns.

Pickup-Style Folding Tailgate

A rear folding panel that acts like a pickup truck tailgate, allowing users to load longer or oversized gear. When opened, it increases storage capacity while maintaining easy access to interior space.

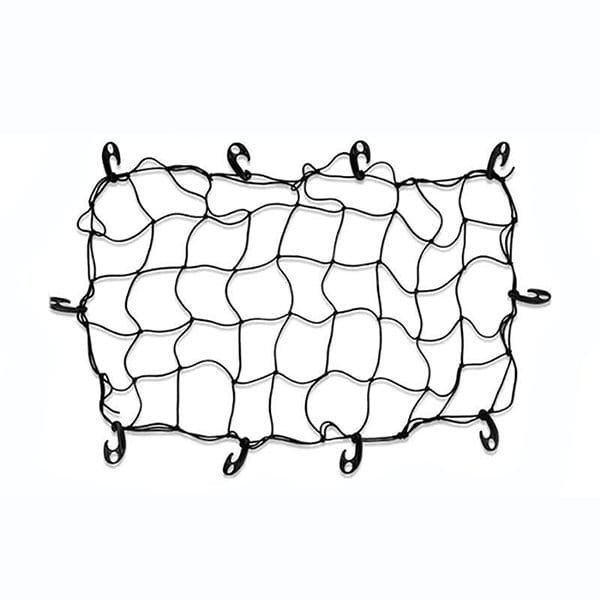

Elastic Retractable Net

Stretchable and easy to attach, this net holds outdoor gear in place during transport. It prevents items from shifting or falling, especially useful for bulky loads like tents, chairs, or coolers.

Detachable Umbrella

An add-on umbrella that clips securely to the wagon, offering shade and light rain protection. Its removable design makes it convenient to install or pack away depending on weather conditions.

Detachable Tabletop

A removable board that mounts securely on top of the wagon to convert it into a camping table. It's ideal for outdoor meals or workspaces, offering a flat, stable surface with quick setup and breakdown.

Detachable Elevated Tabletop

This tabletop includes adjustable-height legs, allowing it to serve as a standing or dining table. Compatible with many folding wagon models, it enhances multi-functionality for outdoor cooking, socializing, or storage.

Detachable Sunshade Top

A fabric canopy that attaches above the wagon, protecting contents from direct sunlight. This shade feature is popular for outdoor markets, pet transport, and kid-friendly designs.

Detachable Storage Bag

Designed to mount on the rear frame, this bag adds extra compartment space. It’s ideal for organizing tools, cables, or personal items, and can be detached and carried separately when needed.

Detachable Push Handle

This adjustable handle allows users to push instead of pull. It can rotate for ergonomic control and height adjustment, improving handling comfort over long distances or uneven paths.

Detachable Folding Baseplate

Installed on the wagon floor, this removable baseplate—made of MDF or PP—reinforces stability. It’s especially useful for multi-fold wagons and can be removed for compact storage.

Carry Bag

Designed with handles and elastic buckles, the carry bag keeps the folded wagon neatly packed. It’s essential for transportation and protects the wagon from dust and scratches when stored indoors or in vehicles.

Customize Your Ideal Folding Wagon

Manufacturing Process

Explore the precision process behind our folding wagon production

Step 1 - Product Design

Product design defines the folding wagon’s structure, dimensions, load capacity, and functionality. It ensures the frame, fabric, wheels, and accessories fit together smoothly. Well-designed wagons enhance user experience, reduce production issues, and allow flexible customization based on market demands and outdoor application scenarios.

Step 2 - Material Incoming

This step involves receiving all core materials including oxford fabric, mesh, and metal tubes. Proper handling ensures materials arrive without damage or deformation. Clear classification and labeling at this stage support efficient flow into inspection and production lines, minimizing production delays and reducing risk of material mix-up.

Step 3 - Material Inspection

Materials are checked for quality and consistency. Fabrics undergo light transmittance and thickness tests, while metal tubes are measured for diameter, wall thickness, and corrosion resistance via salt spray testing. This ensures only qualified materials enter production, guaranteeing product durability and customer satisfaction.

Step 4 - Plastic Injection

Plastic components such as handles, joints, and wheel hubs are injection-molded. Custom molds are used for specific designs, and color can be tailored to client branding. This step is critical for precision fit, strength, and aesthetic consistency across the final product.

Step 5 - Fabric Cutting

Based on digital templates, fabric panels are accurately cut to size. Proper cutting ensures consistent dimensions for later sewing, avoiding misalignment and assembly issues. Precision at this step directly impacts the product's appearance, strength, and structural integration with the metal frame.

Step 6 - Silk-Screen Printing

If requested by the client, logos or graphic designs are printed onto fabric panels using silk-screen techniques. This optional step boosts brand visibility and adds a personalized touch. If not required, the panels proceed directly to sewing, streamlining the workflow.

Step 7 - Fabric Sewing

Panels are sewn into the final wagon cover with reinforced stitching at stress points. Components like side pockets, mesh panels, and foam layers are integrated. After sewing, each cover undergoes a full inspection to ensure structural integrity and finish quality before moving to assembly.

Step 8 - Metal Tube Cutting

Metal tubes are precisely cut using CNC-controlled equipment. Accuracy in length and angle is essential for consistent assembly, folding performance, and weight-bearing capacity. High cutting precision reduces material waste and ensures that subsequent bending and welding steps proceed without issues.

Step 9 - Metal Tube Bending

Each metal tube is bent according to design specifications using custom-made jigs. Operators manually control the bending process to ensure angles and curves meet structural needs. Bending accuracy affects folding smoothness and overall frame alignment.

Step10 - Metal Stress Relieving

After cutting and bending, metal tubes undergo a stress-relief process to eliminate internal tension. This prevents deformation over time and improves long-term structural stability, especially under heavy loads or repeated folding and unfolding cycles.

Step 11 - Punching

Punching creates holes for rivets, fasteners, and joint connections. Custom jigs are used to position holes precisely for later alignment. Accuracy in this step ensures smooth assembly and consistent mechanical strength at all connection points.

Step 12 - Metal Welding

Welding joins key frame parts that require permanent connections, such as wheel supports and handle mounts. Depending on volume and design, either manual or robotic welding is used. Quality welding improves load capacity and overall safety of the wagon structure.

Step 13 - Powder Spraying

The metal frame is sprayed with powder coating in customer-specified colors. This provides a smooth finish, rust resistance, and improved aesthetics. Powder coating also enhances weather resistance, making the wagon suitable for outdoor environments over long periods.

Step 14 - Riveting

Rivets are used to fix joints, hinges, and other non-welded connections. Precision riveting ensures secure and durable assembly, while still allowing required parts to rotate or fold. This step directly affects ease of use and product longevity.

Step 15 - Assembling

All components—including the frame, wheels, fabric, handles, and accessories—are assembled into the complete folding wagon. This step requires careful alignment and quality checks at each stage. Functional testing is performed before final approval.

Step 16 - Product Testing

Each finished wagon undergoes tests such as pull force, weight capacity, wheel rotation, and stability. Only products that pass these tests move on to packaging. This guarantees safety, performance, and compliance with international standards.

Step 17 - Packaging

Folding wagons are folded and packed per client requirements, using branded boxes, protective covers, or custom kits. Packaging must protect the product during shipping while optimizing volume to reduce freight costs. Labeling and barcoding are also done here.

Step 18 - Warehousing

Final products are moved into the warehouse for inventory management and shipping preparation. Organized storage ensures efficient loading and order fulfillment. Warehousing also includes final QA sampling and handling of special packing or shipment instructions.

Get More Details On Folding Wagon Manufacturing Process

Customization Highlight

Personalize folding wagons to reflect your brand’s identity

Fabric Dyeing

Fabric dyeing allows customers to choose their desired wagon fabric color. We offer a wide range of Pantone-matched shades with optional PU/PVC/PE coatings for water resistance. This customization aligns the product with brand aesthetics and improves market differentiation, especially for retail or promotional applications.

Silk-Screen Printing

Silk-screen printing is ideal for simple logos or graphics using one or multiple colors. It ensures sharp, durable branding on the wagon fabric. This method is widely used for company logos, campaign slogans, or iconographic visuals, supporting long-term visibility and brand recognition in outdoor environments.

Thermal Transfer Printing

Thermal transfer printing enables high-definition, multi-color graphics or gradient logos. It’s the best choice for complex designs or full-color branding. The print is bonded to the fabric via heat and pressure, delivering vivid, wear-resistant results that elevate brand quality in competitive retail markets.

Custom Injection

Plastic parts like handles, joints, and wheel hubs are usually in standard black. However, with custom injection molding, we can produce these components in any customer-specified color, reinforcing consistent brand identity and enhancing visual coherence across the entire wagon.

Powder Coating

We offer powder coating for the metal frame in any custom RAL or Pantone color. This not only ensures corrosion resistance and durability but also aligns the wagon with brand or seasonal color themes, increasing product appeal for retail or promotional use.

Leather Label

Leather labels can be laser-engraved or embossed with logos or artwork, then stitched onto the wagon fabric. They add a premium and vintage touch, making them ideal for high-end or lifestyle-oriented product lines. Leather labels reinforce brand craftsmanship and uniqueness.

Rubber Label

Rubber labels are perfect for multi-color logos and embossed 3D branding. They are durable, weather-resistant, and can be sewn onto various positions on the wagon. This option adds tactile texture and helps enhance visibility of the brand in a rugged outdoor environment.

Woven Label

Woven labels provide a refined and professional branding element, showcasing detailed logos or text through woven thread patterns. These are typically sewn onto fabric seams or visible areas, offering long-lasting brand identification even after extended outdoor use.

Washing Label

Washing labels include important care instructions and material composition. These labels can be customized with branding and sewn inside the wagon fabric. They ensure regulatory compliance for international retail and provide end-users with essential usage and cleaning information.

Carry Bag

The carry bag can be printed with custom logos or graphics, ensuring brand exposure even when the wagon is stored or carried. This accessory enhances perceived product value and is especially useful for B2B clients seeking cohesive branding across packaging and accessories.

Hang Tag

Hang tags are attached to the product at the point of sale. They can be customized with logos, product info, QR codes, or brand stories. Hang tags are an effective tool for retail branding, marketing communication, and building a professional presentation.

Manual

A printed guide included with the folding wagon, providing assembly instructions, care guidelines, and brand information. Available in various formats such as folded leaflets or booklets, manuals can be customized with multi-language content, illustrations, and brand-specific styling.

Master Carton

The outer packaging box for bulk shipping, ensuring product safety during transportation. Custom printing is available for branding, product details, and handling instructions, supporting retail and distribution needs.

Share Your Branding Needs With Us

Customer Reviews

Discover client testimonials on our folding wagons and service

FAQs

Here you can find answers to the most common questions about sourcing and customizing our folding wagons

Q1. Can I purchase your products if I’ve never done import business?

- Reply: Yes, whether you’re an individual or a company, we offer full sales support. Except in rare cases where governments require imports under a company name, we provide end-to-end services—from design and development to production, inspection, and door-to-door shipping—for all our partners.

Q2. Can you handle large orders for wholesalers?

- Reply: Absolutely. With a stable supply chain, nearly 20 core partner factories, and over 200 suppliers, we can meet the needs of small retailers, large wholesalers, and chain stores. Our team and factories have extensive experience serving overseas clients.

Q3. What international certifications do your products have?

- Reply: Most of our products meet CE and ASTM standards. If your market requires specific certifications, we can provide test samples and assist you in obtaining the necessary approvals.

Q4. What is the typical process for purchasing your products?

- Reply:

- Contact our sales team, and we’ll evaluate your project based on your needs. You can also learn more about us via video calls, virtual factory tours, on-site visits, or third-party audits.

- After approval, we’ll design products or recommend options based on your requirements.

- Once you confirm the design, we provide a quote with detailed product specs.

- After agreeing on price and lead time, we’ll send a Proforma Invoice (PI) for sample confirmation if needed. You pay the sample fee, and we produce it within 7-15 days, contacting you if adjustments are required.

- We’ll share photos/videos of the sample for approval. If confirmed, we ship it via courier. If changes are needed, we refine it until you’re satisfied.

- After testing the sample, you approve bulk production. We send a bulk PI (or you send a PO after we update pricing and lead time).

- Once order details are finalized, you pay the deposit per agreed terms.

- Production starts after we receive the deposit. We’ll update you with progress, photos, or videos. Packaging is designed and produced during this time.

- 7-10 days before completion, we notify you for inspection (on-site or self-inspection reports provided). If issues arise, we resolve them until you’re satisfied.

- Before shipping, you pay the balance (or per agreed terms for long-term clients).

- After payment, we arrange shipping (your forwarder or ours). If we handle it, shipping costs are paid with the balance.

- We track the shipment and provide updates until you receive the goods. We can assist with import procedures if needed.

- Post-delivery, we offer after-sales support for quality issues to ensure your business runs smoothly.

Q5. Can you provide samples before a bulk order?

- Reply: Yes, we offer paid samples, with fees refundable upon bulk order confirmation (depending on the case). For low-cost samples, we can provide them free if you cover shipping.

Q6. What is the minimum order quantity (MOQ)?

- Reply: MOQ varies by product. Some specific items start at 50-100 pieces, while standard models range from 300-1,000 pieces. For bulk orders, we can adjust flexibly. Contact our team for an exact quote based on your needs.

Q7. How long does production take?

- Reply: Our standard production time is 30-45 days, depending on order timing, product type, quantity, and customization complexity.

Q8. Can you customize products with our logo or design?

- Reply: Yes, our core business is helping clients customize products and add their branding in various forms. This supports your unique brand promotion and sales.

Q9. Do you offer packaging customization, like branded tags or logo printing?

- Reply: Yes, our professional design team can create packaging drafts, discuss options with you, and finalize the best solution for your finished products.

Q10. What are the shipping costs and times from China?

- Reply: Costs depend on order volume and destination. We work with trusted logistics partners and can provide up-to-date quotes for sea, air, road, rail, or combined shipping options.

Q11. Can you provide logistics and transportation services?

- Reply: Yes, as a one-stop service provider, we offer door-to-door logistics if you cover the costs. We’ll recommend multiple shipping options for you to choose from.

Q12. Can you assist with import documents?

- Reply: Yes, we handle export paperwork and guide you through customs processes. Our experience ensures compliance with various market requirements.

Q13. What is your payment policy?

- Reply: For new clients or orders over US$3,000, we require a 30% deposit and 70% before shipment. For repeat clients or large orders, terms are negotiable.

Q14. How do you ensure quality control?

- Reply: Our factories follow ISO 9001:2015 standards, with inspections at every production stage. Reports are available upon request.

Q15. What maintenance or care do your products require?

- Reply: Our textile and metal products need no special upkeep. Just follow the user manual or our sales team’s guidance. Contact us if you have questions.

Q16. What is your warranty or return policy?

- Reply: We offer at least a 1-year warranty for manufacturing defects, with returns handled case-by-case.

Case Studies

Explore how we’ve tailored solutions for our folding wagon clients’ unique needs

Ready To Be Our Business Partner?

Get in touch and boost your business

Expand your product line with premium outdoor gear backed by 12 years of expertise. We help your business grow with custom designs, reliable production, and global logistics. Partner with us for seamless service and innovative solutions. Share your needs, and let’s create something great together!