Outdoor Storage

Introduction

Outdoor storage solutions are essential for organized, efficient, and enjoyable camping experiences. At Kelyland Outdoors, we specialize in manufacturing a wide range of portable storage products tailored to meet the demands of global outdoor brands and wholesalers. With over 12 years of production expertise and strong supply chain partnerships, we deliver rugged and dependable storage options built for challenging outdoor environments.

Our collection includes various hydration storage options such as PC, HDPE, or LDPE water containers, as well as collapsible water bags made of PEVA, TPU, or PVC film with frosted or high-transparency finishes. We also offer foldable water buckets constructed from reinforced PVC or TPU mesh fabric—ideal for campsite washing, cleaning, or water transport. For dry gear protection, our waterproof dry bags are available in PVC or TPU laminated fabrics, including TPU nylon for premium lightweight use.

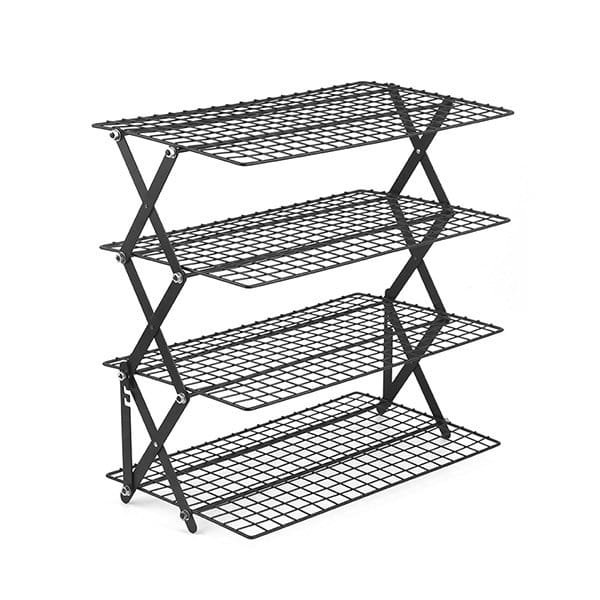

Food preservation is handled with our cooler series, including durable plastic cooler boxes (PP shell + PU or EPS insulation + PE liner), soft coolers, cooler bags, and backpack coolers. These are made from materials such as 840D TPU, 420D TPU, PEVA liners, and closed-cell NBR foam for effective insulation and outdoor durability. Storage bags made of waterproof Oxford, nylon, or polyester fabrics keep your campsite tidy, while foldable boxes (in PP or MDF top lids) and multi-format folding racks (made from iron mesh, aluminum panels, or fabric-laminated MDF) provide structured space-saving solutions.

A new addition to our range—the aluminum storage box—offers heavy-duty protection for high-value gear. Made with reinforced aluminum alloy panels and secure latches, it’s ideal for vehicle storage, overlanding equipment, or long-term outdoor use. This box combines strength, corrosion resistance, and a sleek industrial look for premium outdoor setups.

All products are engineered for portability, durability, and outdoor reliability. We use high-performance materials like PE, TPU, PVC, aluminum, and weather-resistant fabrics. Lightweight, foldable, and easy to pack, our storage gear is perfect for car camping, hiking, expedition travel, glamping, or professional use.

At Kelyland Outdoors, we offer full OEM/ODM customization—from materials and dimensions to color and branding. Whether you’re sourcing for retail, subscription boxes, or promotional events, we support your business with flexible MOQs and quality-assured production. Contact us to explore how our outdoor storage solutions can elevate your product lineup and meet the growing needs of your outdoor customers.

Product Collection

Check out our premium outdoor storage gear lineup for your business

Get Your Custom Outdoor Storage Gear Now

Material Selection

Learn about our outdoor storage gear material choices and functional accessories

Fabric Options

PVC High-Density Mesh Fabric (Polyester or Nylon Fabric)

Durable and abrasion-resistant, PVC high-density mesh fabric is widely used in soft coolers, backpack coolers, and water buckets. Its laminated structure adds strength and waterproof performance, while the dense weave enhances tear resistance—ideal for outdoor products that require ruggedness and flexibility under heavy load.

TPU High-Density Mesh Fabric (Polyester or Nylon Fabric)

TPU high-density mesh fabric combines high elasticity, puncture resistance, and waterproofing. It is used in high-end soft coolers, dry bags, and foldable water buckets. Compared to PVC, TPU offers better cold resistance and environmental friendliness, making it perfect for premium outdoor gear requiring flexible yet strong materials.

TPU Nylon Composite Fabric

TPU nylon composite fabric is lightweight, highly durable, and stretch-resistant. It's commonly used in backpack coolers, dry bags, and advanced storage bags. The TPU coating provides superior waterproofing and long-term outdoor protection, while the nylon base enhances flexibility, making it ideal for foldable and compression-based storage gear.

Oxford Fabric

Oxford fabric is a versatile woven material favored for storage bags, cooler bags, and folding racks. It offers good wear resistance, breathability, and can be treated for water repellency. Often laminated with PE or PU backing, Oxford is a cost-effective and reliable option for foldable or soft-sided outdoor storage solutions.

Polyester Fabric

Polyester fabric is widely used across storage bags, cooler bags, and folding boxes for its strength, UV resistance, and dimensional stability. It's lightweight and easy to clean, making it suitable for general-purpose outdoor storage applications. The fabric can be laminated or coated to improve waterproofing as needed.

Nylon Fabric

Known for its superior tear strength and smooth texture, nylon fabric is used in high-performance dry bags, cooler bags, and folding racks. Compared to polyester, nylon is more elastic and resistant to abrasion, which suits gear exposed to rugged terrain and frequent handling. It’s also ideal for TPU composite laminations.

Mesh Fabric

Mesh fabric is breathable and stretchable, used in cooler bags and backpack cooler side pockets to hold bottles or small accessories. It helps with airflow and quick drying, making it useful in areas needing ventilation or flexibility. Lightweight yet tough, mesh adds practicality to multi-functional outdoor storage designs.

Choose Your Preferred Fabric To Make Outdoor Storage Gear

Plastic Options

PC (Polycarbonate)

PC is a transparent, impact-resistant plastic commonly used in high-end water containers. It offers excellent clarity, high heat resistance, and toughness, making it ideal for long-term water storage outdoors. BPA-free variants are available for food-grade safety and international compliance.

LDPE (Low-Density Polyethylene)

LDPE is lightweight, flexible, and chemically resistant, often used in foldable water containers and water bags. Its softness allows for collapsible designs, while its low-temperature durability makes it suitable for repeated outdoor use. Ideal for basic hydration gear requiring pliability.

HDPE (High-Density Polyethylene)

HDPE is stiffer and more impact-resistant than LDPE. It’s commonly used in water containers and folding boxes. With strong chemical resistance and UV stability, HDPE is ideal for rugged outdoor environments where strength and durability are essential.

PE (Polyethylene)

General PE refers to both LDPE and HDPE types. It’s widely used in water bags, liners, and foldable storage due to its lightweight, flexibility, and low cost. PE is food-safe, making it suitable for hydration products and inner linings in coolers.

TPU (Thermoplastic Polyurethane)

TPU is a premium material used in soft coolers, backpack coolers, and dry bags. It provides superior elasticity, abrasion resistance, and cold flexibility. Environmentally friendly and non-toxic, TPU is preferred in high-end waterproof and insulated gear.

PVC (Polyvinyl Chloride)

PVC is tough, waterproof, and economical. It’s widely used in dry bags, water buckets, and coolers. Laminated with mesh fabric, it creates durable outdoor materials. However, compared to TPU, PVC is less environmentally friendly and performs poorly in extreme cold.

PEVA (Polyethylene Vinyl Acetate)

PEVA is a soft, non-toxic, PVC-free material used as the inner liner for cooler bags and backpack coolers. It provides waterproofing and is safe for food contact. PEVA also has good flexibility and is odorless, making it ideal for insulated food storage applications.

TPE (Thermoplastic Elastomer)

TPE is a soft, flexible, and durable material ideal for collapsible water buckets. It combines rubber-like elasticity with plastic processability, enabling easy folding and rebound. TPE performs well in outdoor environments, offering high tear resistance and water sealing.

PP (Polypropylene)

PP is lightweight, rigid, and resistant to heat and chemicals. It’s commonly used in cooler boxes, plastic storage boxes, and plastic components. It’s also suitable for injection-molded lids, hinges, and folding box structures. PP is recyclable and food-safe.

Choose Your Preferred Plastic To Make Outdoor Storage Gear

Metal Options

Aluminum Sheet and Tube

Aluminum sheets and tubes are lightweight, corrosion-resistant, and ideal for folding rack shelves and side frames. Their high strength-to-weight ratio supports stable structure with easy portability. Surface powder spraying enhances weather resistance and appearance, making them suitable for rugged outdoor storage solutions.

Iron Mesh

Iron mesh offers excellent strength and rigidity, commonly used for shelf panels in folding racks. Its open-grid structure allows ventilation and drainage, essential for outdoor environments. Finished with durable powder coating, it resists rust and corrosion, extending lifespan and maintaining clean aesthetics during field use.

Iron Sheet

Iron sheets provide strong structural support, often applied to the outer shell of metal cooler boxes. They are impact-resistant and cost-effective, offering good insulation protection when paired with inner foam. The powder-sprayed surface protects against moisture, UV, and scratches—suitable for long-term outdoor storage demands.

Customize Your Ideal Outdoor Storage Gear

Insulation Options

EPS Foam

EPS foam provides lightweight and cost-effective insulation for plastic cooler boxes. It offers decent thermal retention by trapping air within its cellular structure. Though not as durable as PU, it's suitable for short-term outdoor use and basic cold chain storage.

PU Foam

PU foam delivers high-performance insulation and excellent cold retention in cooler boxes. It has a denser structure than EPS, providing longer ice preservation. This material is ideal for premium outdoor coolers used in extended trips, fishing, or overlanding.

XPS Foam

XPS foam offers a closed-cell structure with better moisture resistance and compressive strength than EPS. It can be used as an optional insulation material in hard-sided cooler boxes where added rigidity and water resistance are needed in humid or rugged environments.

EVA Foam

EVA foam is flexible, lightweight, and shock-absorbent, used as a mid-level insulator in cooler bags. It balances insulation and cushioning, suitable for recreational use, such as picnics and family camping, where portability and basic performance are essential.

NBR Foam

NBR foam is a premium closed-cell insulator with excellent resistance to temperature, oil, and moisture. Used in soft coolers and backpack coolers, it ensures extended cooling performance while maintaining flexibility and durability, ideal for serious outdoor enthusiasts.

EPE Foam

EPE foam is a lightweight, economical option used in cooler bags. It offers basic thermal insulation and shock resistance, making it suitable for light outdoor activities or as an entry-level option for budget-friendly insulated bags.

PEVA Aluminum Film

PEVA aluminum film is used as the inner lining for cooler bags, providing food-safe waterproofing and heat-reflective insulation. It’s easy to clean, lightweight, and eco-friendly—perfect for direct contact with food and drinks in daily use or short trips.

Customize Your Ideal Outdoor Storage Gear

Accessory Options

Airtight Waterproof Zipper

Made from TPU or PVC-coated fabric materials, this airtight zipper is commonly used in dry bags, soft coolers, and backpack coolers. It prevents water or air from leaking, maintaining insulation and keeping contents completely sealed even in wet or rugged outdoor environments.

Nylon Shoulder Strap

Attached to soft coolers and cooler bags, this adjustable nylon strap offers a comfortable, hands-free carrying solution. Reinforced with durable stitching and plastic or metal buckles, it ensures reliable performance on hiking, camping, or beach trips.

Webbing Plastic Hook

An essential accessory on folding racks, this plastic hook combined with nylon webbing can hang collapsible cups, camping pots, or mess kits. It helps organize utensils and kitchenware conveniently, optimizing space in camp kitchens or picnic setups.

Handle

The handle on plastic folding boxes provides a convenient grip for lifting and moving. Typically made from strong PP, it's designed to fold flat when not in use, enhancing portability and space-saving for organized transport or storage.

MDF Lid

Used as an alternative to PP plastic lids on folding storage boxes, this MDF lid can feature a wood grain surface and laser-engraved logo. It adds an aesthetic touch while offering flat support, turning the box top into a mini tabletop during outdoor use.

Detachable Waterproof Bag

Placed inside folding boxes, this removable waterproof bag allows temporary water storage. Made from durable PVC or TPU materials, it’s leak-proof and easy to clean, making it perfect for washing tasks, food prep, or general water holding at the campsite.

Plastic Lid

Designed for collapsible silicone water buckets, this lid prevents water from splashing during transport. Made from food-grade PP, it’s lightweight and secure-fitting, improving portability and cleanliness when carrying or storing water outdoors.

Retractable Handle and Wheels

High-end cooler boxes feature this setup for easier movement. The telescopic handle and built-in wheels enable smooth transport across campsites or parking lots, ideal for large-capacity coolers used in long stays, BBQs, or car camping.

Ice Pack

This reusable pack contains dry ice crystals made from inorganic salts and absorbent resin. It requires water injection before first use, forming a cooling gel once fully absorbed. After freezing, it provides long-lasting cold retention in cooler boxes, soft coolers, and cooler bags for outdoor food preservation.

Ice Gel Container

These reusable containers are filled with polymer gel for long-lasting cold retention. Once frozen, they can be placed inside coolers or cooler bags to keep contents chilled. Ideal for camping, fishing, or emergency cold storage outdoors.

Faucet with Extendable Hose

Installed on plastic water containers, this faucet with pull-out hose controls flow and direction. It's perfect for camping kitchens, letting users pour water directly for washing, cooking, or hand cleaning without removing the container.

Cleaning Brush

A necessary accessory for water containers, this brush removes sediment and residue from interior walls. Designed with a long handle and soft bristles, it ensures hygiene and safety when storing drinking water or food-grade liquids during outdoor trips.

Customize Your Ideal Outdoor Storage Gear

Manufacturing Process

Explore the precision process behind our outdoor storage gear production

Fabric Storage Gear Production Flow

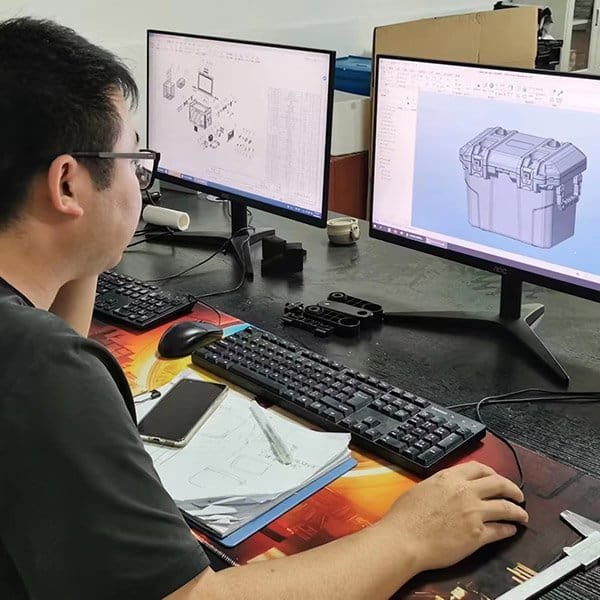

Step 1 - Product Design

Our design team develops custom layouts for soft coolers, backpack coolers, and storage bags, focusing on usability, insulation needs, stitching structure, and client branding preferences before sampling and tooling.

Step 2 - Material Incoming

We source premium materials like 840D TPU fabric, PVC mesh, PEVA, Oxford cloth, and insulation foams. All materials are received and tagged by batch for tracking and quality assurance.

Step 3 - Material Inspection

Fabrics are tested for thickness, coating adhesion, waterproof performance, and color consistency. Only qualified rolls proceed to cutting, ensuring durability and production stability.

Step 4 - Fabric Cutting

Using computer-controlled machines or manual tools, fabrics and linings are cut into precise panels based on design templates to minimize waste and optimize sewing efficiency.

Step 5 - Heat Pressing

Heat pressing bonds fabric layers or accessories using high-frequency heat. This step is crucial for soft coolers and backpack coolers, enhancing waterproof sealing and structure retention.

Step 6 - Sewing

Panels are stitched together with heavy-duty thread. Seam types and positions vary by product type—ensuring strength, leak resistance, and ergonomic fit in use.

Step 7 - Forming

Soft and backpack coolers are shaped using high-frequency plastic welding machines. This ensures airtight insulation compartments and watertight seams without needle holes.

Step 8 - Product Inpection

Each product undergoes full QC: seam strength tests, leak detection, insulation performance, and zipper smoothness. Only products passing tests move to final packaging.

Step 9 - Packaging

Products are cleaned and packed with instructions, hang tags, and logos. Packaging varies—PE bags, color boxes, or carry bags—depending on client needs and product type.

Step 10 - Warehousing

All items are stored in a dust-free, moisture-controlled warehouse. Inventory is coded by SKU for efficient picking, quality traceability, and timely delivery to global clients.

Get More Details On Fabric Outdoor Storage Manufacturing Process

Plastic Storage Gear Production Flow

Step 1 - Product Design

Our engineers design each plastic item—like folding boxes or cooler shells—based on functionality, strength, and portability. Prototypes are created to test structure, fit, and custom branding feasibility before moving into production.

Step 2 - Material Incoming

We source high-quality plastic resins such as PP, PE, and HDPE. Materials arrive in raw pellet form, stored under dry, clean conditions to maintain processing integrity.

Step 3 - Material Inspection

All plastic pellets are inspected for consistency, color accuracy, and purity. Moisture content and flow index are tested to ensure proper molding performance.

Step 4 - Mold Installation

Molds for injection or blow molding are precisely installed. These determine the product’s final shape, thickness, and detail level, supporting both structural strength and customization.

Step 5 - Dry Blending

Plastic pellets are mixed with color masterbatch to create client-specific colors. This step ensures consistent coloration and material stability throughout the injection or blow molding process.

Step 6 - Blow Molding

Blow molding forms hollow plastic water tanks. Heated material is inflated inside the mold, creating lightweight, seamless, and leak-proof containers suitable for outdoor use. For water containers manufacturing only.

Step 7 - Injection Molding

Used for cooler shells and folding boxes, injection molding shapes plastic parts with high precision, producing durable components with clean lines, fine details, and consistent dimensions.

Step 8 - Silk-Screen Printing

Logos, product labels, and instructions are printed on plastic surfaces using durable silk-screen ink, offering high visibility and wear-resistant branding on storage boxes and water tanks.

Step 9 - Foaming

PU foam is injected between outer and inner cooler shells. This step creates a high-density insulation layer to maintain cold storage for extended outdoor use. Fo hard cooler box manufacturing only.

Step 10 - Assembly

All parts are manually or semi-automatically assembled—handles, wheels, spouts, lids, and locks—ensuring proper fit, function, and strength before packaging and testing.

Step 11 - Ice Gel Box Production

Gel packs are filled with water-absorbing polymer powder. After water is added, they become a cooling gel. These packs are frozen and inserted into coolers for temperature control.

Step 12 - Product Testing

Gel packs are filled with water-absorbing polymer powder. After water is added, they become a cooling gel. These packs are frozen and inserted into coolers for temperature control.

Step 13 - Packaging

Products are packed with protective film, user manuals, and branding. Depending on client needs, we offer PE bags, color boxes, carry bags, and master cartons.

Step 14 - Warehousing

All goods are stored in a dry, clean, and temperature-controlled warehouse. Inventory is organized by SKU to ensure fast dispatch and consistent delivery timelines.

Get More Details On Plastic Outdoor Storage Manufacturing Process

Want To Get More Details On Metal Outdoor Storage Gear Manufacturing Process?

The production processes largely mirror those used in manufacturing metal camping tables.

Customization Highlight

Personalize outdoor storage gear to reflect your brand’s identity

Custom Pigment Powder

Colored pigment powder is pre-mixed with plastic granules during dry blending to match your brand’s exact Pantone. Ideal for customizing folding boxes, water containers, and cooler boxes.

Custom Color Masterbatch

Color masterbatch is added during injection or blow molding. This ensures accurate color reproduction for plastic parts like cooler lids, folding box panels, or container bases.

Silk-Screen Printing

A flexible branding method for applying logos on plastic, metal, or fabric surfaces. Commonly used on cooler bags, soft coolers, aluminum boxes, and folding racks.

Thermal Transfer Printing

Allows full-color or high-definition branding on curved or textured surfaces. Perfect for detailed graphics on soft coolers, water bags, or plastic lids.

Mold Recess Engraving

Your logo can be engraved into the plastic mold, making it embossed or recessed directly into the surface—durable and tamper-proof. Great for plastic folding boxes or cooler lids.

Laser Marking

A precise, permanent branding method used on aluminum and MDF surfaces. Ideal for cooler box handles, folding rack shelves, or aluminum storage boxes.

Laser Cutting

Creates clean, decorative logo cut-outs on sheet metal. Often used on iron or aluminum shelves of folding racks, offering a premium, ventilated look with brand visibility.

Embossing

Applies raised logo effects to metal panels. Common for aluminum box lids or metal storage shelves, giving a rugged and professional branding result.

Sticker

Vinyl or paper logo stickers can be applied to products or packaging for low-cost, high-flexibility branding. Works across all product types and boxes.

Hang Tag

A printed brand tag tied to the product with string or band. Useful for retail presentation of storage bags, coolers, and collapsible gear.

Woven Label

Fabric logo tags sewn into seams of textile products such as cooler bags, soft coolers, or backpacks. Reinforces brand identity and long-term product recognition.

Washing Label

A care label stitched inside cooler bags or fabric storage items. Includes branding, washing instructions, and material content to help customers use the product correctly.

Manual

Custom instruction booklets can include your brand design, usage directions, safety tips, and after-sales contact. Inserted in packaging for plastic and fabric gear.

Box

Retail or brown box packaging can be custom-printed. Options include color boxes with graphics or plain boxes with logos—fit for cooler boxes, racks, and folding containers.

Share Your Branding Needs With Us

Customer Reviews

Discover client testimonials on our outdoor storage gear and service

FAQs

Here you can find answers to the most common questions about sourcing and customizing our outdoor storage gear

Q1. Can I purchase your products if I’ve never done import business?

- Reply: Yes, whether you’re an individual or a company, we offer full sales support. Except in rare cases where governments require imports under a company name, we provide end-to-end services—from design and development to production, inspection, and door-to-door shipping—for all our partners.

Q2. Can you handle large orders for wholesalers?

- Reply: Absolutely. With a stable supply chain, nearly 20 core partner factories, and over 200 suppliers, we can meet the needs of small retailers, large wholesalers, and chain stores. Our team and factories have extensive experience serving overseas clients.

Q3. What international certifications do your products have?

- Reply: Most of our products meet CE and ASTM standards. If your market requires specific certifications, we can provide test samples and assist you in obtaining the necessary approvals.

Q4. What is the typical process for purchasing your products?

- Reply:

- Contact our sales team, and we’ll evaluate your project based on your needs. You can also learn more about us via video calls, virtual factory tours, on-site visits, or third-party audits.

- After approval, we’ll design products or recommend options based on your requirements.

- Once you confirm the design, we provide a quote with detailed product specs.

- After agreeing on price and lead time, we’ll send a Proforma Invoice (PI) for sample confirmation if needed. You pay the sample fee, and we produce it within 7-15 days, contacting you if adjustments are required.

- We’ll share photos/videos of the sample for approval. If confirmed, we ship it via courier. If changes are needed, we refine it until you’re satisfied.

- After testing the sample, you approve bulk production. We send a bulk PI (or you send a PO after we update pricing and lead time).

- Once order details are finalized, you pay the deposit per agreed terms.

- Production starts after we receive the deposit. We’ll update you with progress, photos, or videos. Packaging is designed and produced during this time.

- 7-10 days before completion, we notify you for inspection (on-site or self-inspection reports provided). If issues arise, we resolve them until you’re satisfied.

- Before shipping, you pay the balance (or per agreed terms for long-term clients).

- After payment, we arrange shipping (your forwarder or ours). If we handle it, shipping costs are paid with the balance.

- We track the shipment and provide updates until you receive the goods. We can assist with import procedures if needed.

- Post-delivery, we offer after-sales support for quality issues to ensure your business runs smoothly.

Q5. Can you provide samples before a bulk order?

- Reply: Yes, we offer paid samples, with fees refundable upon bulk order confirmation (depending on the case). For low-cost samples, we can provide them free if you cover shipping.

Q6. What is the minimum order quantity (MOQ)?

- Reply: MOQ varies by product. Some specific items start at 50-100 pieces, while standard models range from 300-1,000 pieces. For bulk orders, we can adjust flexibly. Contact our team for an exact quote based on your needs.

Q7. How long does production take?

- Reply: Our standard production time is 30-45 days, depending on order timing, product type, quantity, and customization complexity.

Q8. Can you customize products with our logo or design?

- Reply: Yes, our core business is helping clients customize products and add their branding in various forms. This supports your unique brand promotion and sales.

Q9. Do you offer packaging customization, like branded tags or logo printing?

- Reply: Yes, our professional design team can create packaging drafts, discuss options with you, and finalize the best solution for your finished products.

Q10. What are the shipping costs and times from China?

- Reply: Costs depend on order volume and destination. We work with trusted logistics partners and can provide up-to-date quotes for sea, air, road, rail, or combined shipping options.

Q11. Can you provide logistics and transportation services?

- Reply: Yes, as a one-stop service provider, we offer door-to-door logistics if you cover the costs. We’ll recommend multiple shipping options for you to choose from.

Q12. Can you assist with import documents?

- Reply: Yes, we handle export paperwork and guide you through customs processes. Our experience ensures compliance with various market requirements.

Q13. What is your payment policy?

- Reply: For new clients or orders over US$3,000, we require a 30% deposit and 70% before shipment. For repeat clients or large orders, terms are negotiable.

Q14. How do you ensure quality control?

- Reply: Our factories follow ISO 9001:2015 standards, with inspections at every production stage. Reports are available upon request.

Q15. What maintenance or care do your products require?

- Reply: Our textile and metal products need no special upkeep. Just follow the user manual or our sales team’s guidance. Contact us if you have questions.

Q16. What is your warranty or return policy?

- Reply: We offer at least a 1-year warranty for manufacturing defects, with returns handled case-by-case.

Case Studies

Explore how we’ve tailored solutions for our outdoor storage gear clients’ unique needs

Ready To Be Our Business Partner?

Get in touch and boost your business

Expand your product line with premium outdoor gear backed by 12 years of expertise. We help your business grow with custom designs, reliable production, and global logistics. Partner with us for seamless service and innovative solutions. Share your needs, and let’s create something great together!